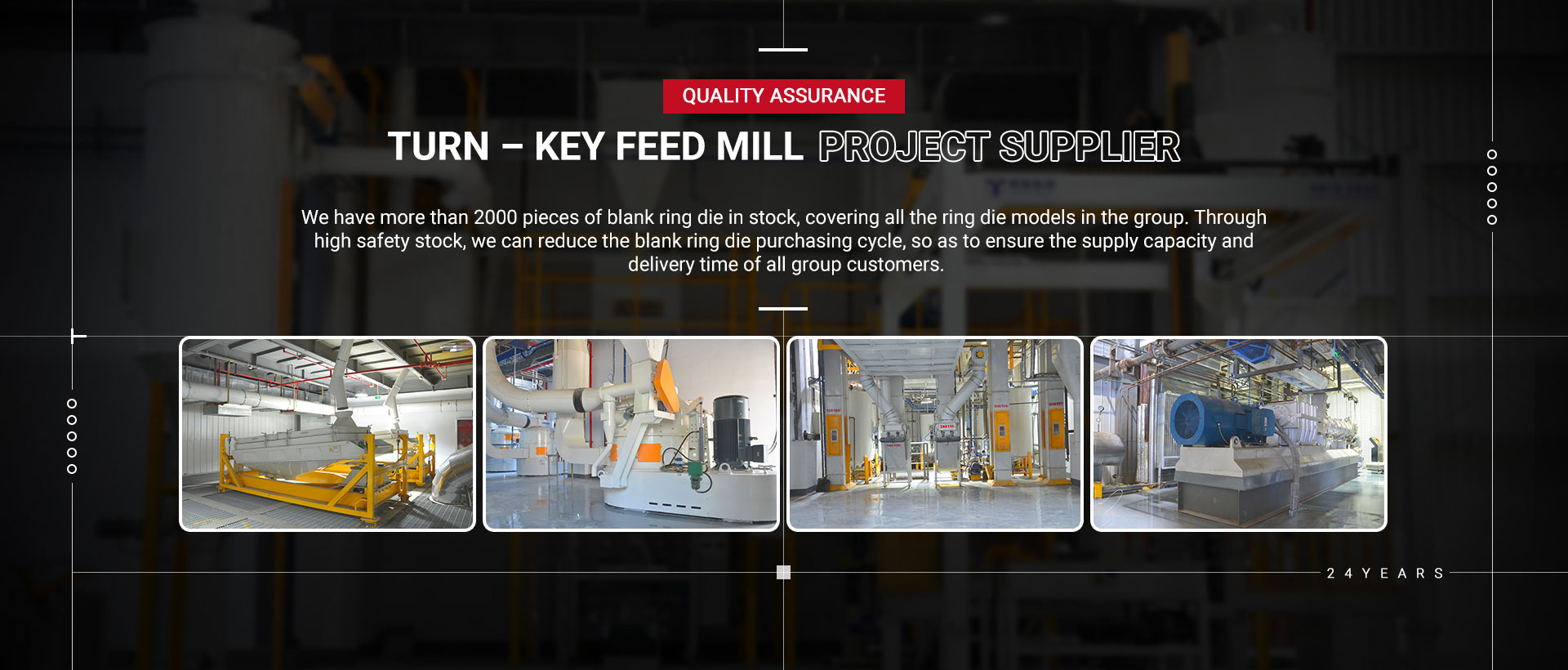

Top-quality Feed Mill Machinery for Efficient Feed Production

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. is a leading manufacturer and supplier of high-quality feed mill machinery in China. With years of expertise and experience in the industry, we are dedicated to providing innovative and efficient solutions for feed production. Our feed mill machinery is designed and manufactured to meet the specific needs of feed producers, offering reliable performance and cost-effective operation. From raw material handling, grinding, mixing, and pelletizing, our machinery covers all aspects of the feed production process. At Shanghai Zhengyi Machinery, we are committed to delivering top-notch products and excellent customer service. We work closely with our clients to understand their requirements and provide tailored solutions to meet their needs. If you are looking for a reliable and reputable supplier of feed mill machinery, look no further than Shanghai Zhengyi Machinery. Contact us today for quotes and to learn more about our products and services.

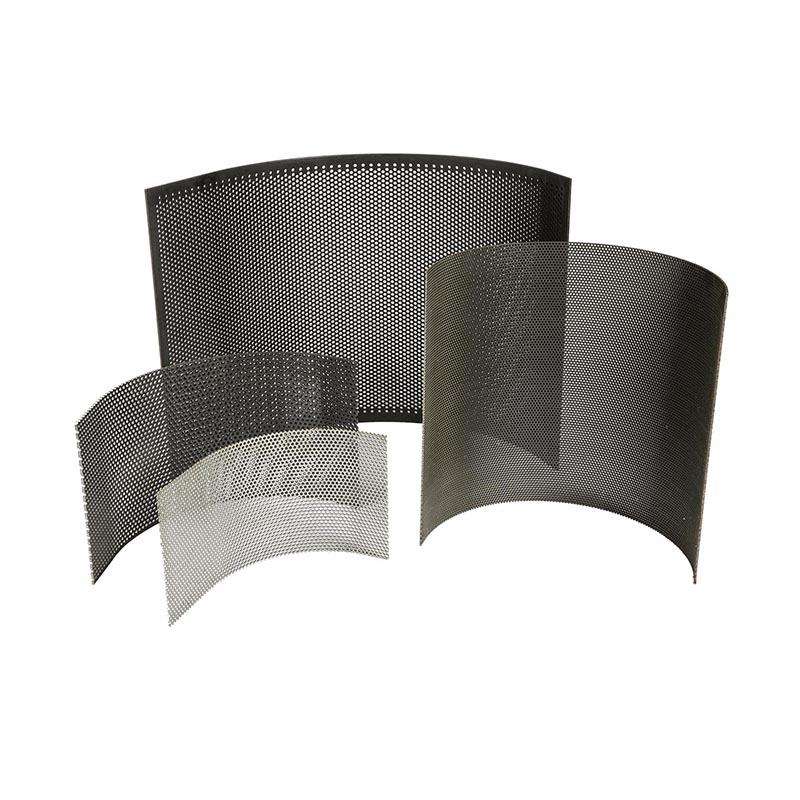

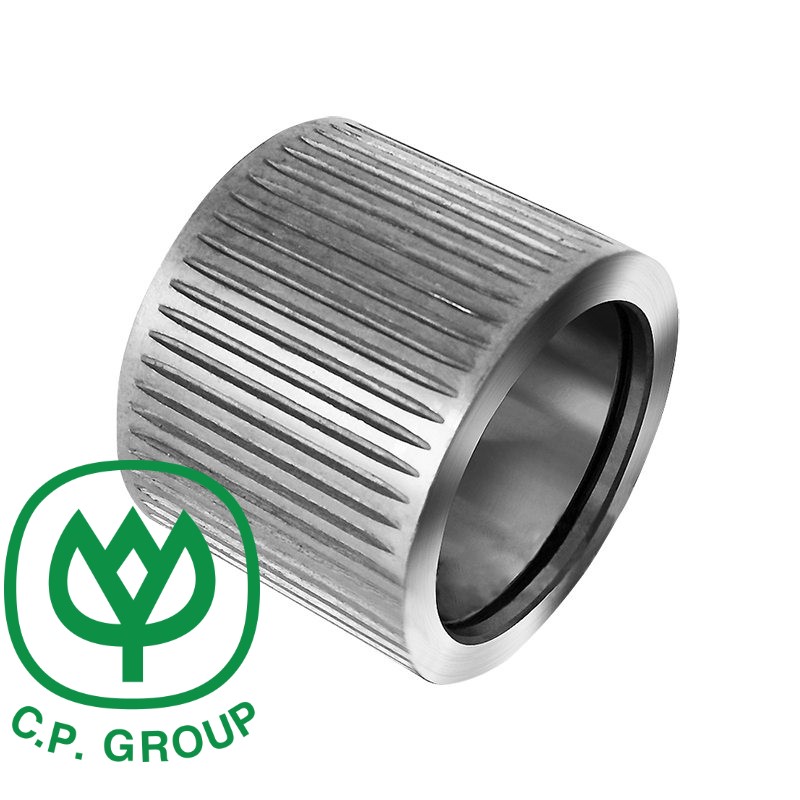

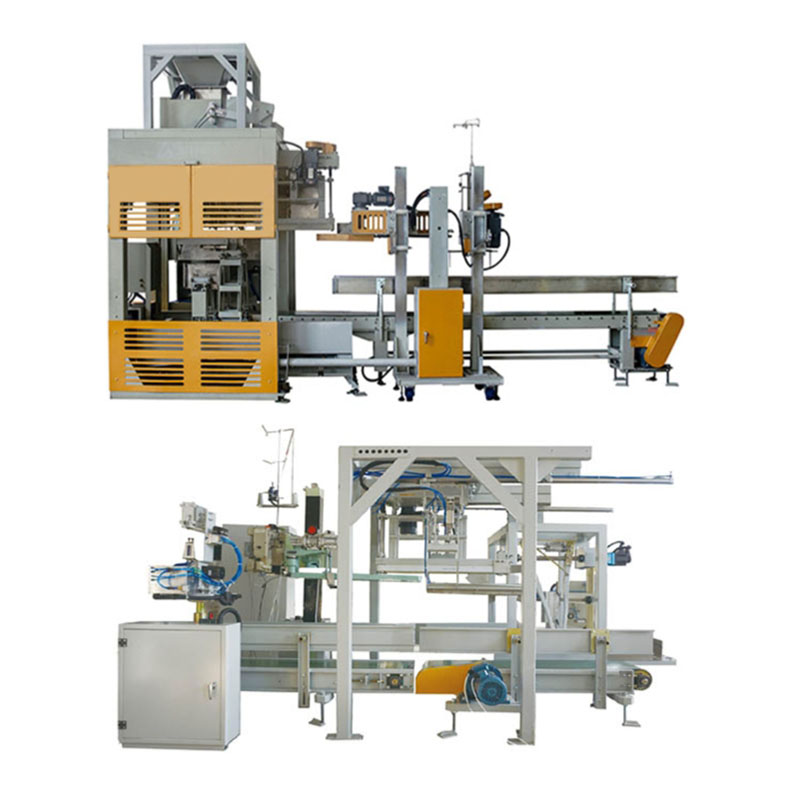

Related Products