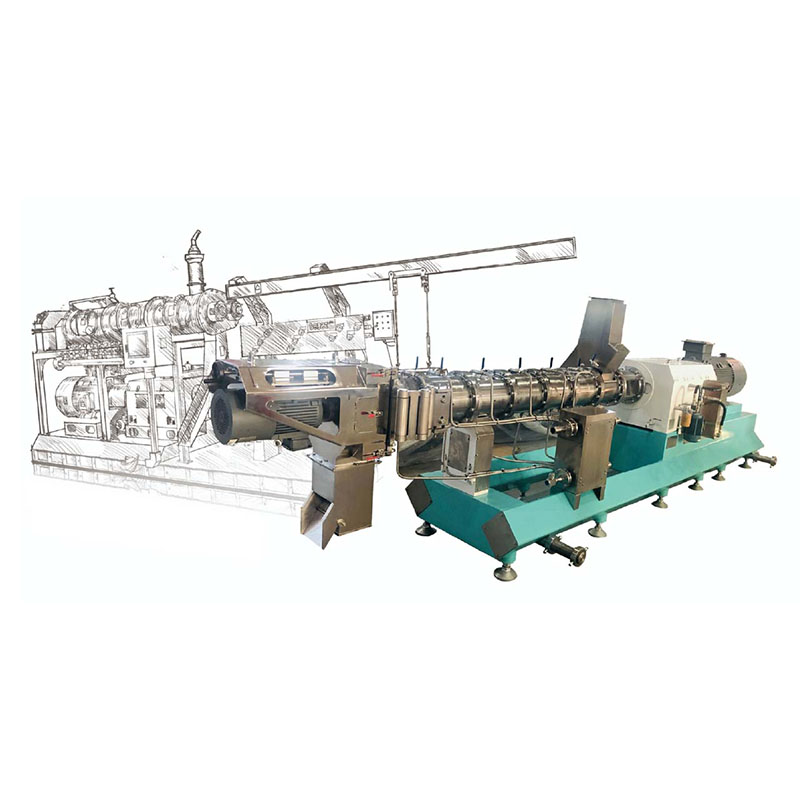

Enhance Your Manufacturing Processes with a Conical Twin Screw Extruder

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. is a leading manufacturer and supplier of Conical Twin Screw Extruders in China. Our state-of-the-art extruders are designed to provide high-quality and efficient processing for various industries. The Conical Twin Screw Extruder is designed for high output and superior mixing performance, making it ideal for a wide range of applications including PVC pipe, profile, and sheet production. It features advanced control systems for precise temperature and speed control, ensuring consistent and reliable processing. At Zhengyi Machinery, we are committed to providing our customers with top-of-the-line equipment that meets the highest standards of quality and performance. Our Conical Twin Screw Extruders have been praised by our clients for their durability, efficiency, and low maintenance requirements. Contact us today for quotes and more information about our Conical Twin Screw Extruders. Choose Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. as your trusted partner for all your extruder needs.

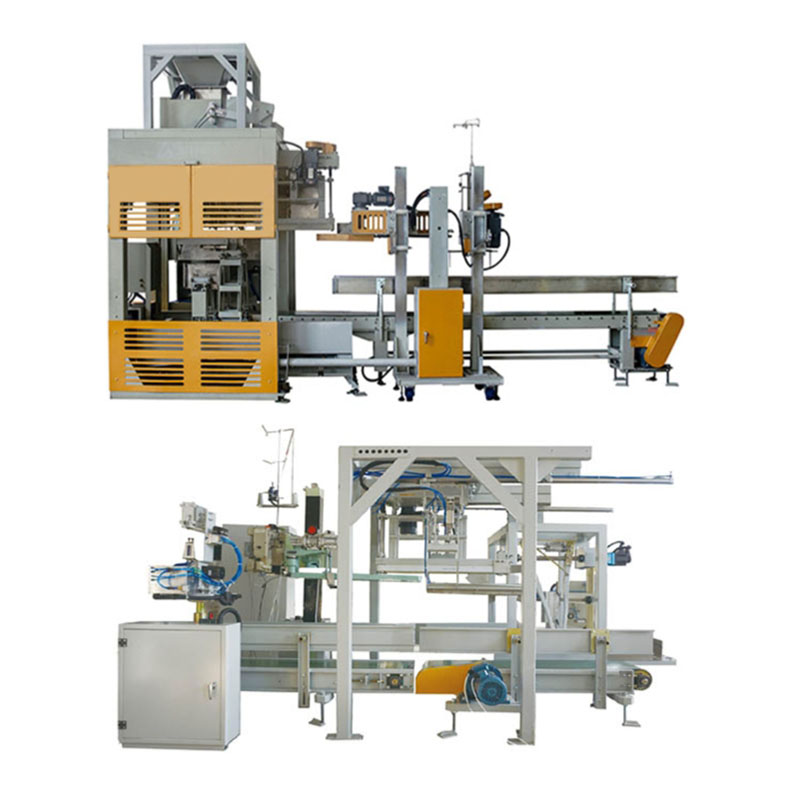

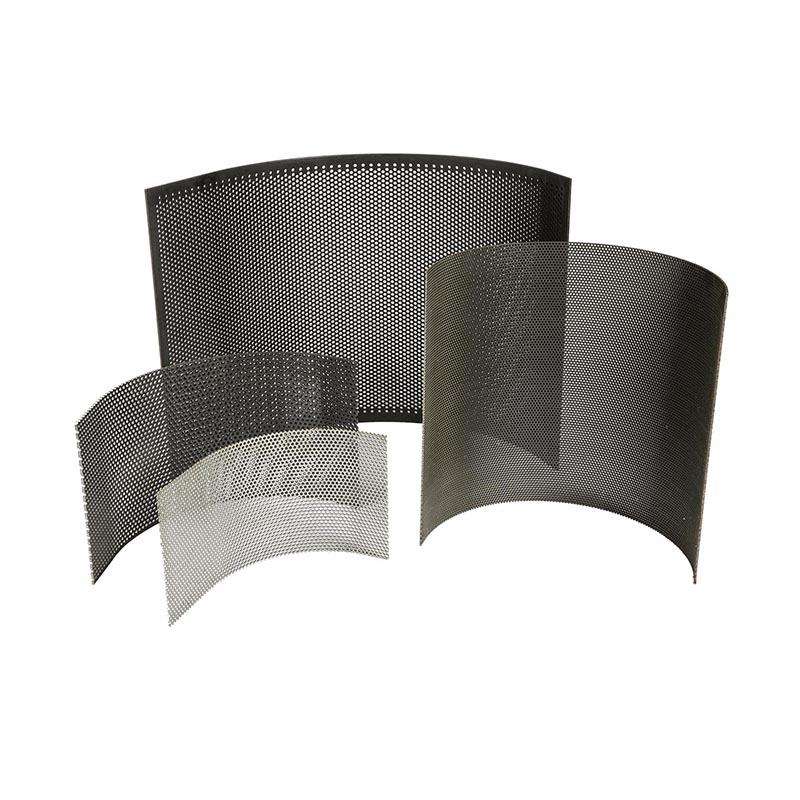

Related Products