High-Quality Home Wood Pellet Mill for Efficient Pellet Production

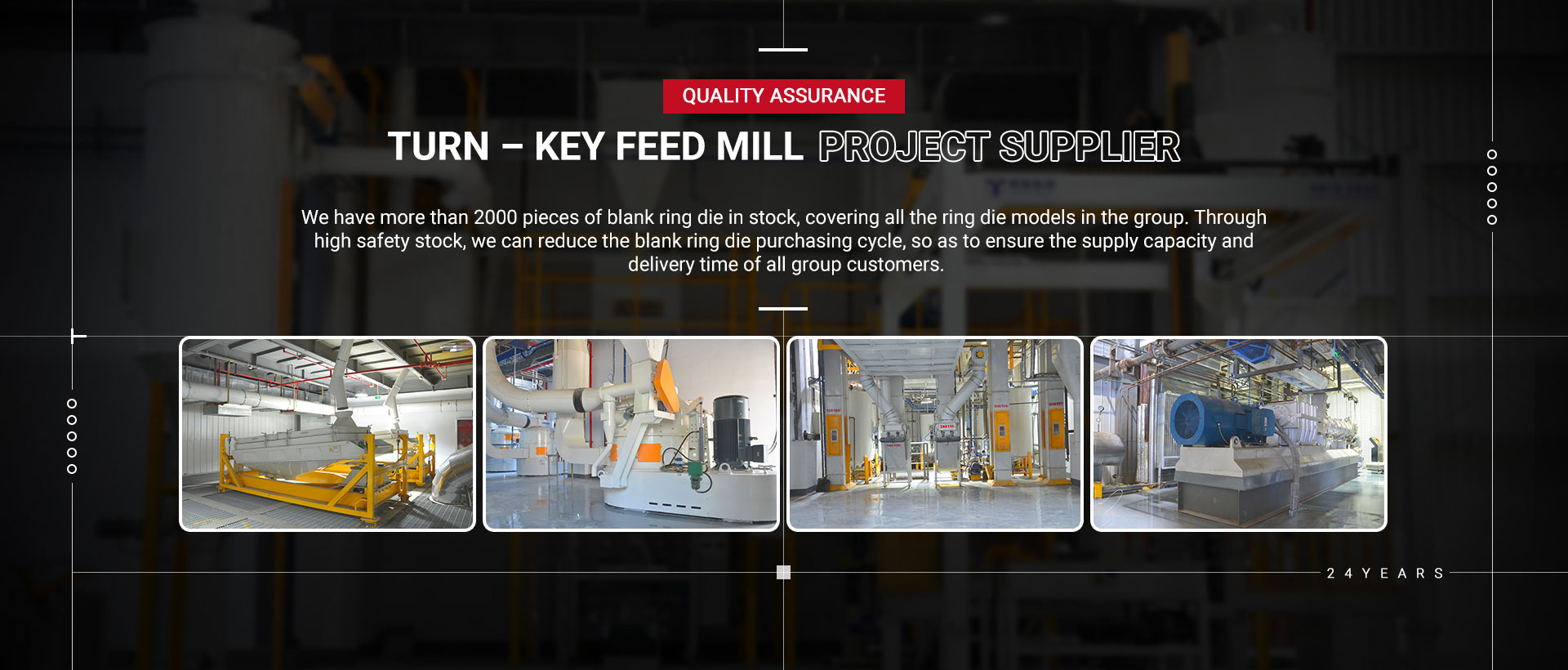

Welcome to Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., a leading manufacturer and supplier of home wood pellet mills in China. Our top-quality wood pellet mills are designed to efficiently produce high-quality wood pellets from various types of wood materials. Whether you are a homeowner looking to make your own wood pellets for heating or a small business looking to produce wood pellets for sale, our home wood pellet mill is the perfect solution for you. Our home wood pellet mill is compact, easy to use, and equipped with advanced technology to ensure efficient and consistent pellet production. With our wood pellet mill, you can turn waste wood materials into valuable pellets for heating or commercial use. Plus, our customer service team is always ready to provide you with quotes and assist you with any questions or inquiries you may have. Choose Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. as your reliable partner for high-quality home wood pellet mills in China. Contact us today for more information and quotes on our products.

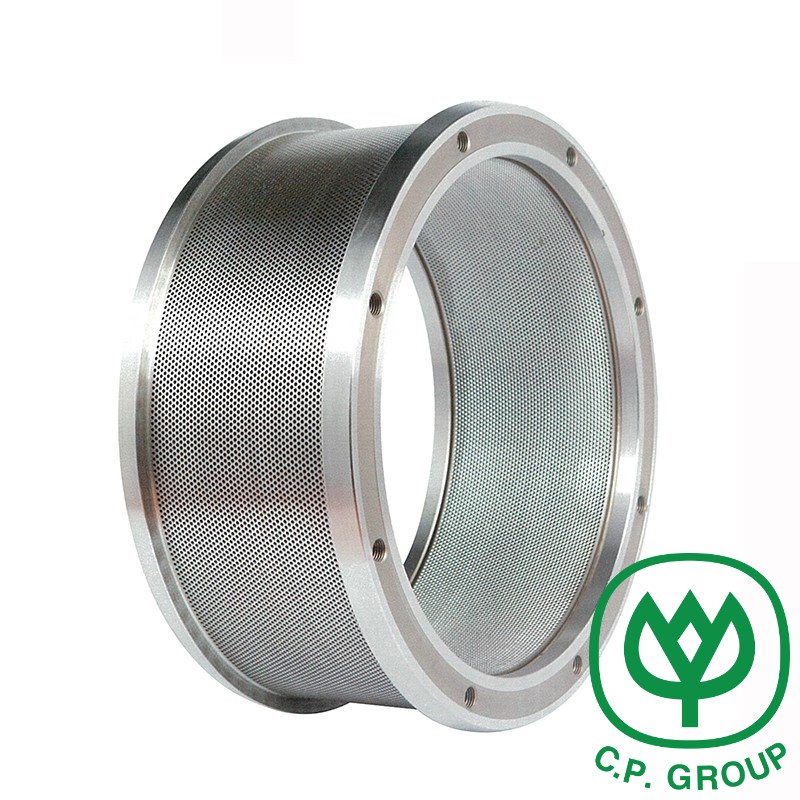

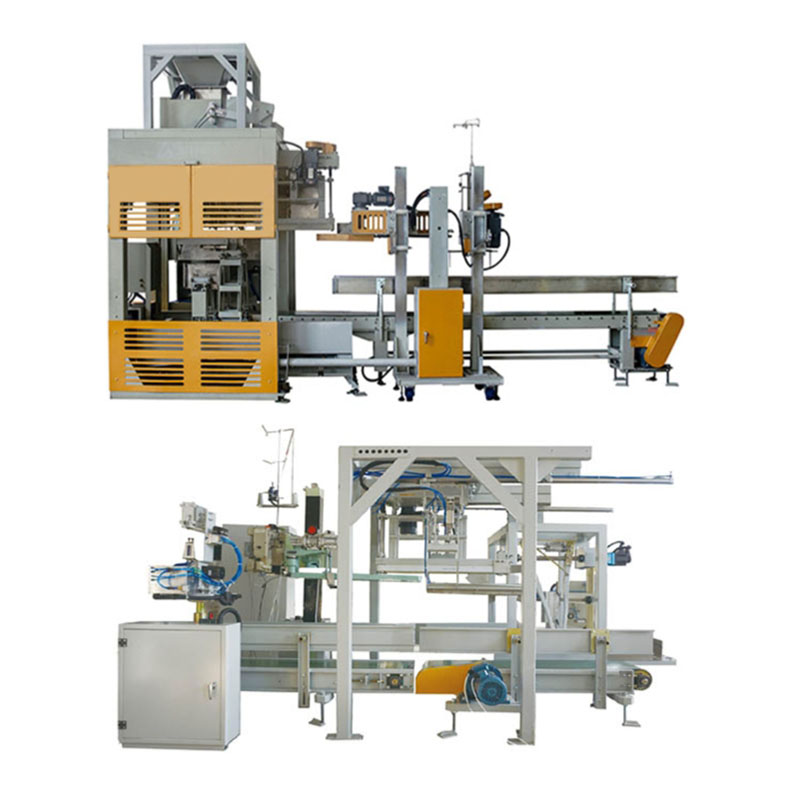

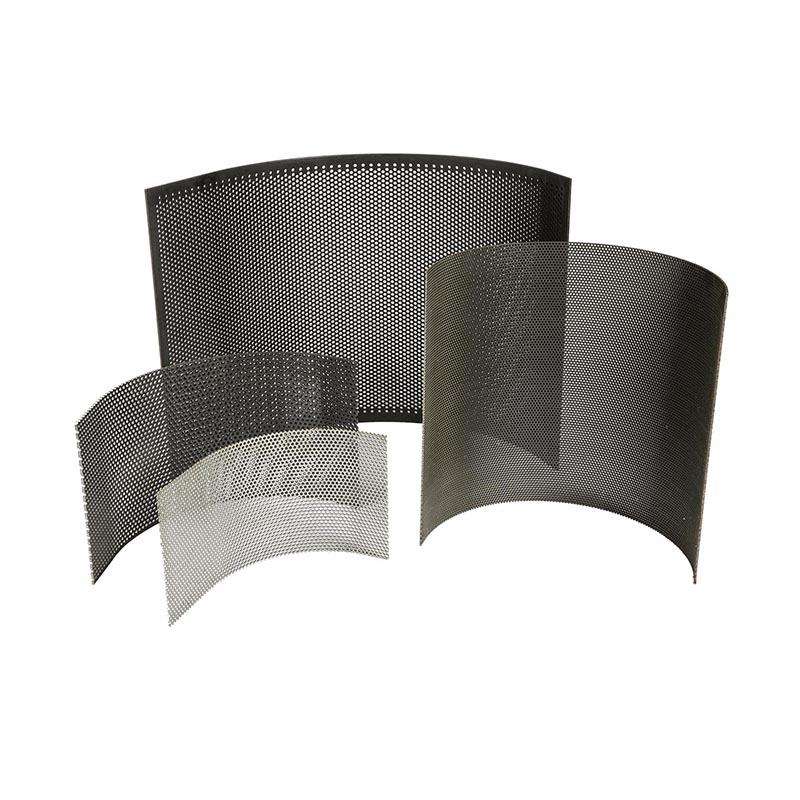

Related Products