Maximize Livestock Feed Efficiency with a High-Quality Roller Mill

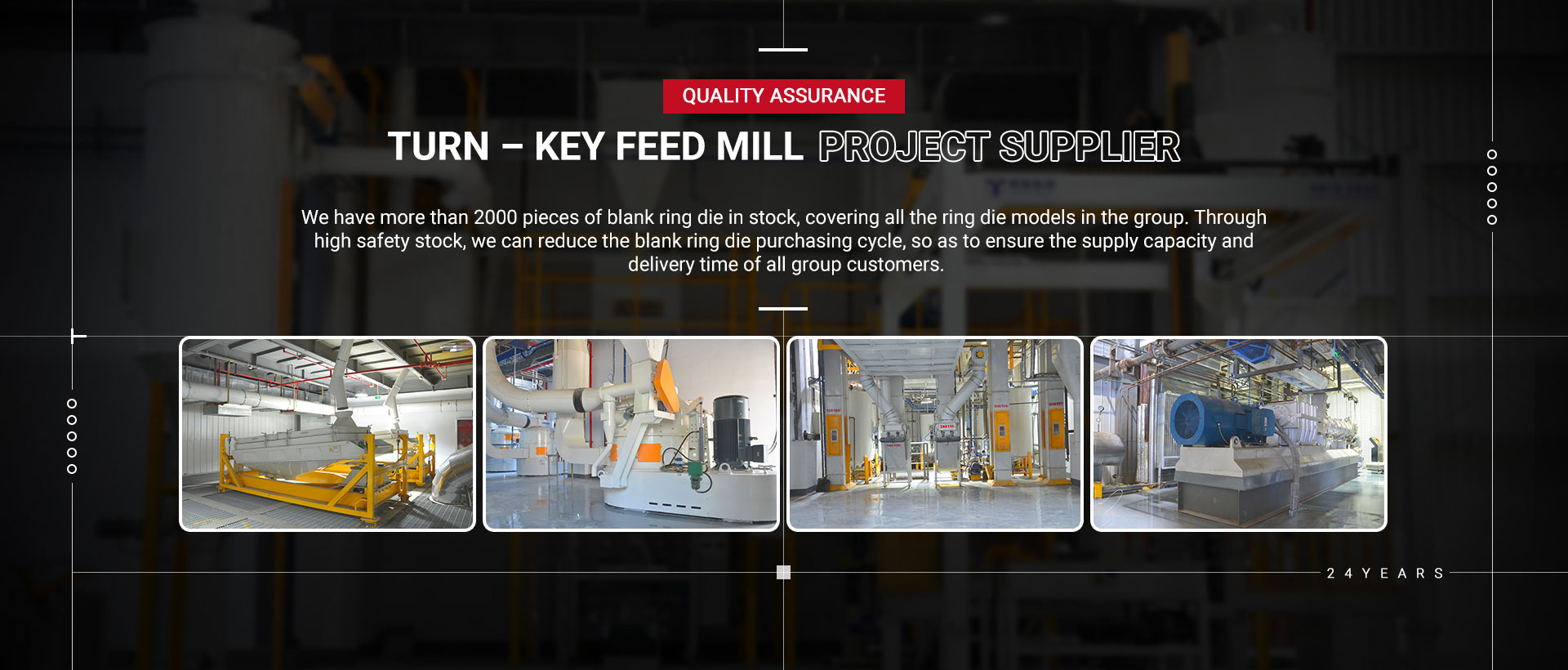

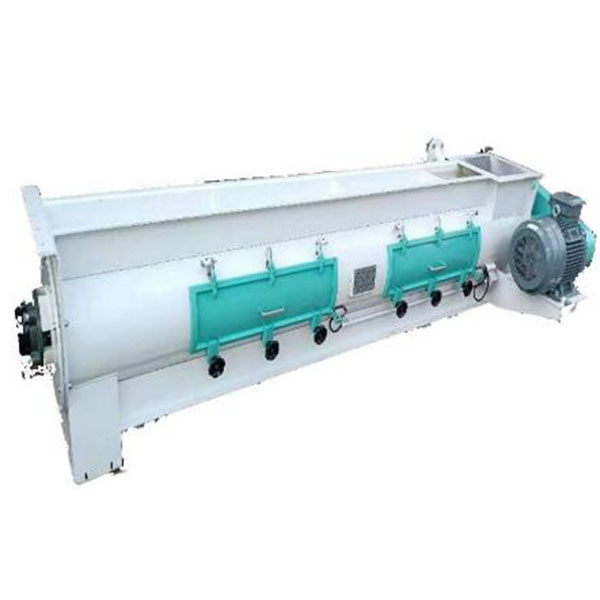

Welcome to Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., your trusted manufacturer and supplier of livestock feed roller mills in China. Our company is dedicated to providing high-quality feed processing equipment to help improve the efficiency and productivity of your livestock operations. Our Livestock Feed Roller Mill is designed to efficiently grind and crush a variety of grains and materials, ensuring the proper nutrition and digestibility of feed for your livestock. With our state-of-the-art technology and precision engineering, our roller mill delivers consistent and uniform particle size, resulting in better feed conversion and overall animal health. We have a team of experienced engineers and technicians who are committed to delivering reliable and durable equipment that meets the specific needs of our customers. We offer competitive quotes and excellent customer service to ensure a seamless purchasing experience. Choose Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. as your trusted partner for all your livestock feed processing needs. Contact us today to learn more about our Livestock Feed Roller Mill and how it can benefit your operation.

Related Products