01

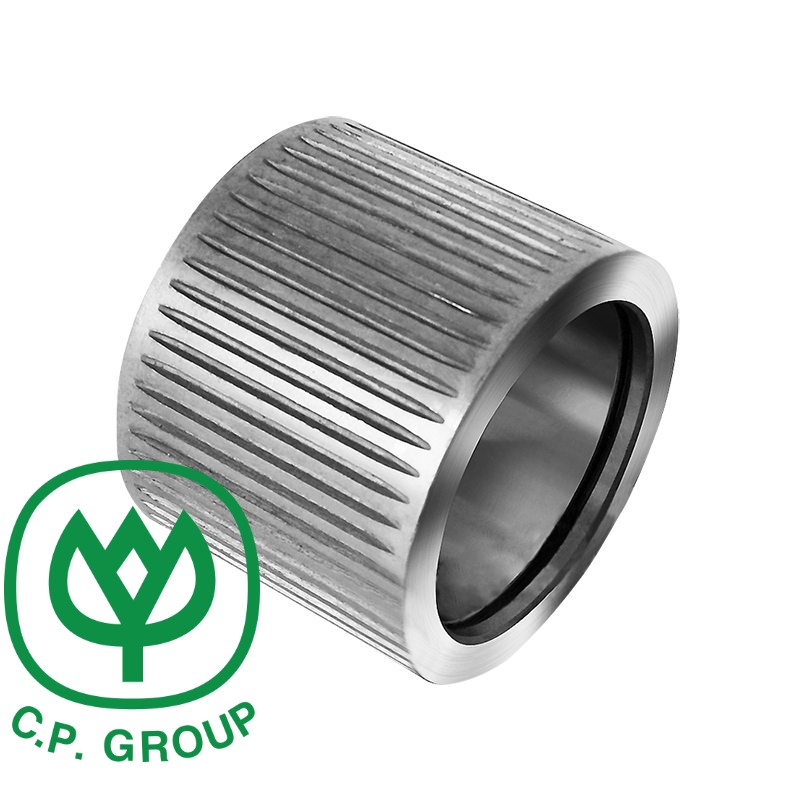

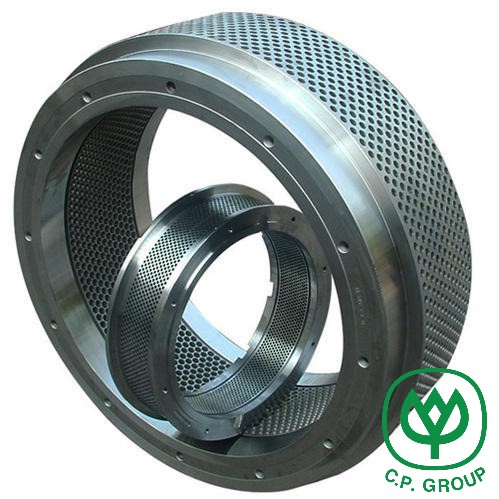

MUNCH pellet mill ring die

2023-12-26 14:47:37

1.Select high-quality raw materials, secondary steelmaking, degassing billet; 2.Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials; 3.Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output; 4.Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life; 5.According to the principle and requirements of the customer to design compression ratio and strength; 6.Microscopic examination to ensure product quality; 42Crmo / 20CrMnTi alloy steel ring die processing technology: Cutting→Forging→Normalizing→Roughing→Tempering→Finishing→Drilling (Expanding) Hole→Carburizing→Grinding→(Excluding Oxidation Layer) →Pressure Testing→(Phosphorus Passivation)→Coating Antirust Oil→Check and save options; X46Cr13 / 4Cr13 stainless steel ring die processing technology: Cutting→Forging→Roughing→Normalizing→Finishing→Quenching and tempering→ › Finishing→Drilling hole→Nitriding→Polishing→Pressure test→ Coating resistance→Rusty oil→Check and save options; S/N Model Size (mm) OD*ID*overall width*pad width Hole size mm 1 MUNCH455/170 560*455*244*170 1-12 2 MUNCH520/80 636*520*182*80 1-12 3 MUNCH520/178 616*520*222*178 1-12 4 MUNCH520/210 618*520*264*210 1-12 5 MUNCH650/105 819*650*234*105 1-12 6 MUNCH660/178 799*660*234*178 1-12 7 MUNCH660/228 799*660*284*228 1-12 8 MUNCH660/265 799*660*323*265 1-12 9 MUNCH850/260 1003*850*349*261 1-12 10 MUNCH935/225 1078*935*310*225 1-12

view

detail

01

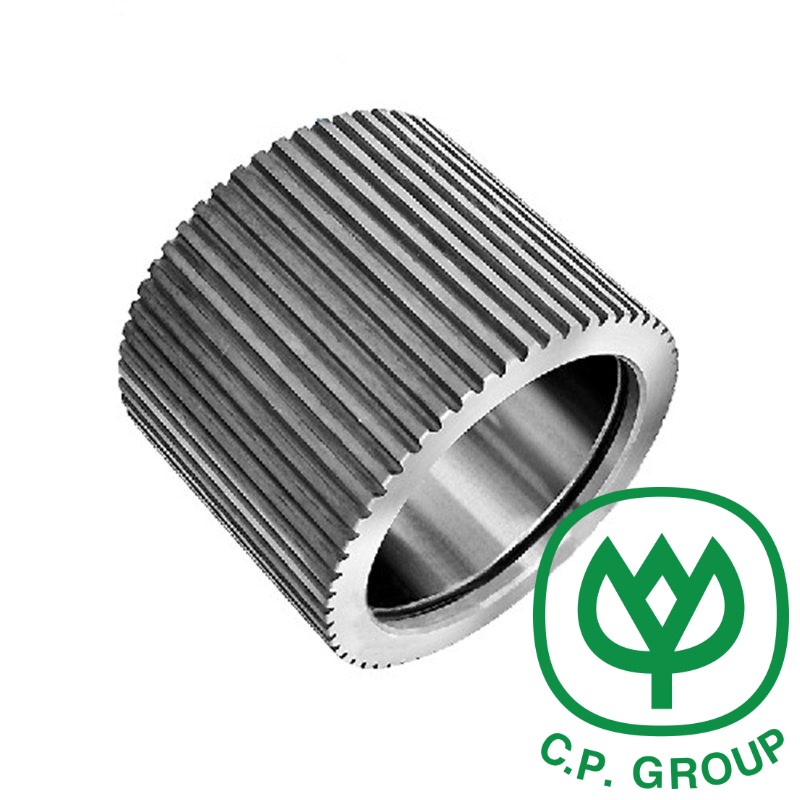

SZLH series pellet mill ring die

2023-12-26 14:49:19

1.Select high-quality raw materials, secondary steelmaking, degassing billet; 2.Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials; 3.Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output; 4.Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life; 5.According to the principle and requirements of the customer to design compression ratio and strength; 6.Microscopic examination to ensure product quality; 42Crmo / 20CrMnTi alloy steel ring die processing technology: Cutting→Forging→Normalizing→Roughing→Tempering→Finishing→Drilling (Expanding) Hole→Carburizing→Grinding→(Excluding Oxidation Layer) →Pressure Testing→(Phosphorus Passivation)→Coating Antirust Oil→Check and save options; X46Cr13 / 4Cr13 stainless steel ring die processing technology: Cutting→Forging→Roughing→Normalizing→Finishing→Quenching and tempering→ › Finishing→Drilling hole→Nitriding→Polishing→Pressure test→ Coating resistance→Rusty oil→Check and save options; S/N Model Size (mm) OD*ID*overall width*pad width Hole size mm 1 MUNCH455/170 560*455*244*170 1-12 2 MUNCH520/80 636*520*182*80 1-12 3 MUNCH520/178 616*520*222*178 1-12 4 MUNCH520/210 618*520*264*210 1-12 5 MUNCH650/105 819*650*234*105 1-12 6 MUNCH660/178 799*660*234*178 1-12 7 MUNCH660/228 799*660*284*228 1-12 8 MUNCH660/265 799*660*323*265 1-12 9 MUNCH850/260 1003*850*349*261 1-12 10 MUNCH935/225 1078*935*310*225 1-12

view

detail

01

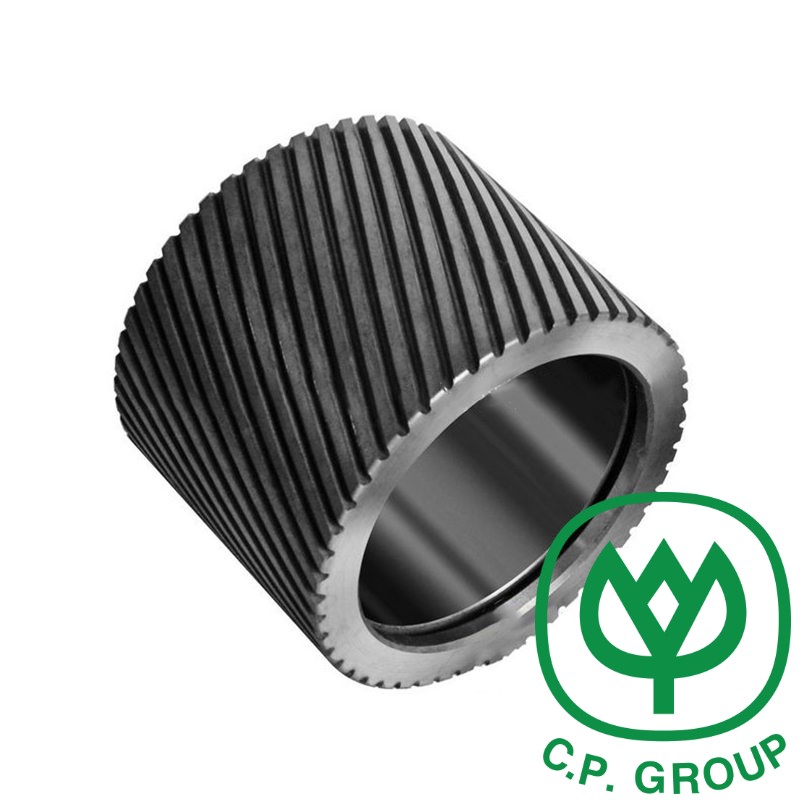

Zhengchang pellet mill ring die

2023-12-26 14:54:40

1.Select high-quality raw materials, secondary steelmaking, degassing billet; 2.Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials; 3.Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output; 4.Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life; 5.According to the principle and requirements of the customer to design compression ratio and strength; 6.Microscopic examination to ensure product quality; 42Crmo / 20CrMnTi alloy steel ring die processing technology: Cutting→Forging→Normalizing→Roughing→Tempering→Finishing→Drilling (Expanding) Hole→Carburizing→Grinding→(Excluding Oxidation Layer) →Pressure Testing→(Phosphorus Passivation)→Coating Antirust Oil→Check and save options; X46Cr13 / 4Cr13 stainless steel ring die processing technology: Cutting→Forging→Roughing→Normalizing→Finishing→Quenching and tempering→ › Finishing→Drilling hole→Nitriding→Polishing→Pressure test→ Coating resistance→Rusty oil→Check and save options; S/N Model Size (mm) OD*ID*overall width*pad width Hole size mm 1 MUNCH455/170 560*455*244*170 1-12 2 MUNCH520/80 636*520*182*80 1-12 3 MUNCH520/178 616*520*222*178 1-12 4 MUNCH520/210 618*520*264*210 1-12 5 MUNCH650/105 819*650*234*105 1-12 6 MUNCH660/178 799*660*234*178 1-12 7 MUNCH660/228 799*660*284*228 1-12 8 MUNCH660/265 799*660*323*265 1-12 9 MUNCH850/260 1003*850*349*261 1-12 10 MUNCH935/225 1078*935*310*225 1-12

view

detail

01

Granulator accessories spindle

2022-02-16 08:08:00

Equipment specification • Spindle, spindle platen adopts forging process, after quenching and tempering, CNC machine tool processing, the middle of the oil hole in the use of deep hole gun drilling, can provide zhengchang, CPM, Buhler and other types of granulator spindle, can also be customized for customers.

view

detail

01

Pellet Mill Spare Parts Main Shaft

2022-02-16 08:02:54

Product Description The shaft is one of the key components of a pelletizer, the quality of the piece and of the production process is very important. The shaft is the central element of the rotor and is the heart of the press, it must be able to withstand the continuous vibrations and shocks generated by the pelleting process. The shaft is built in hardened and tempered 38NiCrMo3 steel. Its head is protected by a thick chrome coating of about 0.2 mm as protection against abrasion and corrosion. The quality of the turning and milling processes is important, it must guarantee not only the strict dimensional tolerances and the surface quality, but also the shape tolerances: circularity, concentricity, parallelism and perpendicularity.

view

detail

01

Hollow Shaft For Pellet Machine

2022-02-16 07:56:03

Hollow Shaft For Pellet Machine The hollow shaft introducing foreign advanced production equipment and fabrication technology, using imported balloon, the shaft is casting by aluminum alloy, shaft body plating chromium, accurate assembly, convenient to use and long operate life Introduction of Hollow Shaft 1. The hollow shaft introducing foreign advanced production equipment and fabrication technology, using imported balloon, the shaft is casting by aluminum alloy, shaft body plating chromium, accurate assembly, convenient to use and long operate life. When used with my companys professional configuration of the air gun mouth filling gas, to make the shaft of off-axle apperance uniform expansion, thereby lock nitrogen-treated barrel, when unloading, press on deflated mouth to deflated, then nitrogen-treated barrel can be unloaded. 2.Performance and advantages: hollow shaft in practical applications, it has advantages of convenient operation, quick, without damage rolls etc. 3.Mechanically Expanded shafts were made of aluminum alloy or steel construction, all air expansion shaft we can according to customer's drawing. Main Features of Hollow Shaft 1. Applicable for Both vertical and horizontal biomass pellet mill: wood pellet mill, sawdust pellet mill, grass pellet mill, straw pellet mill, crop stalk pellet machine, alfalfa pellet mill etc. 2. Applicable for feed pellet machine, all kinds of animal/poultry/livestock/aquatic feed pellet machine.

view

detail

01

Front roller support of Pellet mill Spare Parts

2022-02-16 07:52:19

Product Description Front roller support of Pellet mill Spare Parts The front roller support rigidly constraints, from the front side, the two shafts of the rollers and has a fundamental role in the lubrication of their bearings: ● The grease passes through a series of channels obtained inside it, connecting the lubrication pump with the roller bearings. ● The precision of the processes and the perfect clamp closure avoid lubricant leaks. ● The two front deflectors are fixed to the plate with clamps and can be oriented. This is an exclusive of La Meccanica which allows the control of the perfect distribution of the product to be pelleted on the working surface of the die. The plate is in S235JR steel and is machined with a planar grinding to guarantee perfect flatness. The boring operations of the holes are performed with a very narrow tolerance of +/- 0.2 mm. After processing, the plate is nickel-plated with an electrolytic process in order to increase resistance to corrosion and abrasion. The surface coating is suitable for contact with food according to NSF 51.

view

detail

01

deflector of Pellet mill Spare parts

2022-02-16 07:47:48

Product Description DEFLECTOR In order for the pellet mill to express its maximum production capacity, the product to be pelletized must be distributed regularly and uniformly on the perforated surface of the die. The deflectors are used to collect the product that passes from the conveyor to the rotary feed cone and distribute it on the perforated surface of the die. The deflectors are made of AISI 340 steel (the cylindrical shank) and C40 (the blade) The deflectors are adjustable and the correct adjustment of their inclination guarantees perfect product distribution and consequent regular consumption of the die. The “hardened by flame” blade is shaped with a particular parabolic profile designed to adapt to the profile of the rotary feed cone.

view

detail

01

Professional manufacturer Single Shaft Mixer

2021-12-11 09:36:38

Single Shaft Mixer is mainly used for coating, dry powder and chemical industry Used to mix various dry powder materials metered in proportion. Also can be used to mix feed and cooperate with other feed processing equipment in medium and small-sized farms.

view

detail

01

Professional manufacturer Series Contioner

2021-12-11 09:47:16

Feed Mash Conditioner A pellet mill consists of a (a) variable speed feeder unit, (b) conditioning chamber, (c) die-and-roller assembly, and (d) electric motor. The variable speed feeder unit is generally a screw conveyor and controlled with a variable frequency drive (VFD).

view

detail

01

Best price Jacket Contioner

2021-12-13 03:34:35

SZLH series of feed pellet mill adopts three-layer jacket conditioner, the material can be fully cooked, meet special needs and ensure quality of final aquatic feed. Main driving adopts high precision gear transmission, the capacity can be improved about 20% compared to the belt transmission, and with low energy-consumption.

view

detail

01

Best price Wide Type Hammer Mill

2021-12-13 03:43:15

To meet the fine grinding requirement of the aquatic feed pellet production, our company developed the new generation aquatic feed hammer mill.

view

detail

01

Pulverizer

2021-12-13 03:49:31

Used for grinding and micro-grinding such raw ingredients as wheat, maize, dehydrated fish, shrimp shells, defatted soybean, monosodium glutamate, sugar, medicines, dying material intermediates, ore, etc.

view

detail

01

Professional manufacturer Series Heat Retaintioner

2021-12-13 06:08:20

Pelleting of animal feed occurs extensively throughout the feed manufacturing industry and steam conditioning plays an important role in this process. electrical energy consumption, and steam flow rate during the pelleting process.

view

detail

01

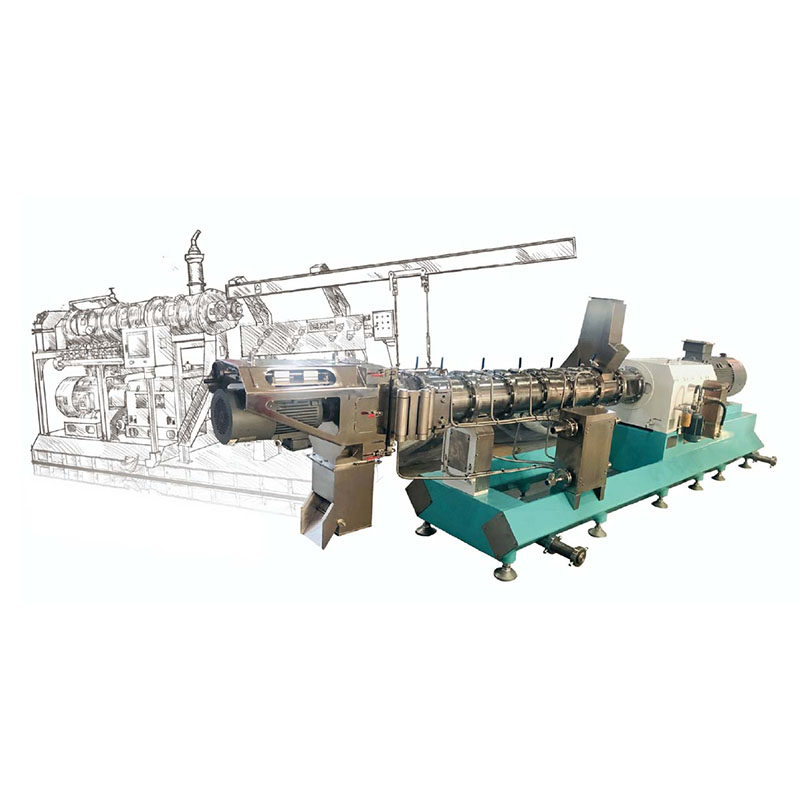

Professional manufacturer Twin Screw Extruder

2021-12-13 06:11:20

A wide range of applications, as can produce floats, slow sinks, sinks (Shrimp feed, crabs feed, etc.) Modularization of basic structure, through the combination of different spiral units, can meet the production of

Different formula materials.

view

detail