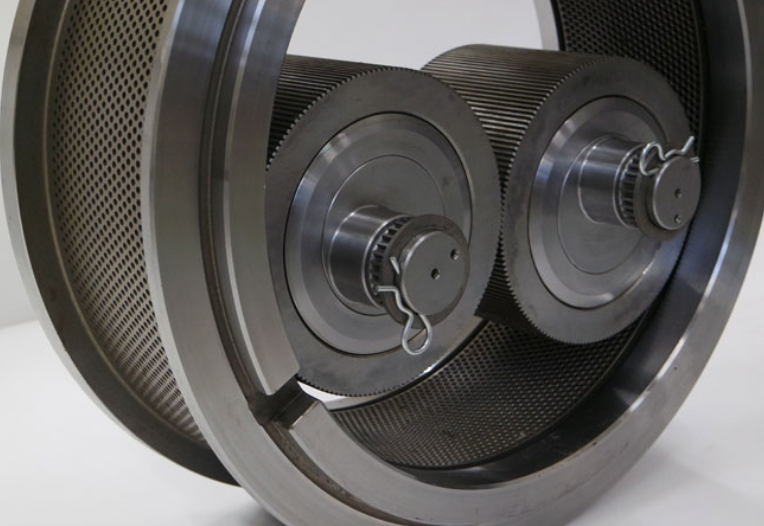

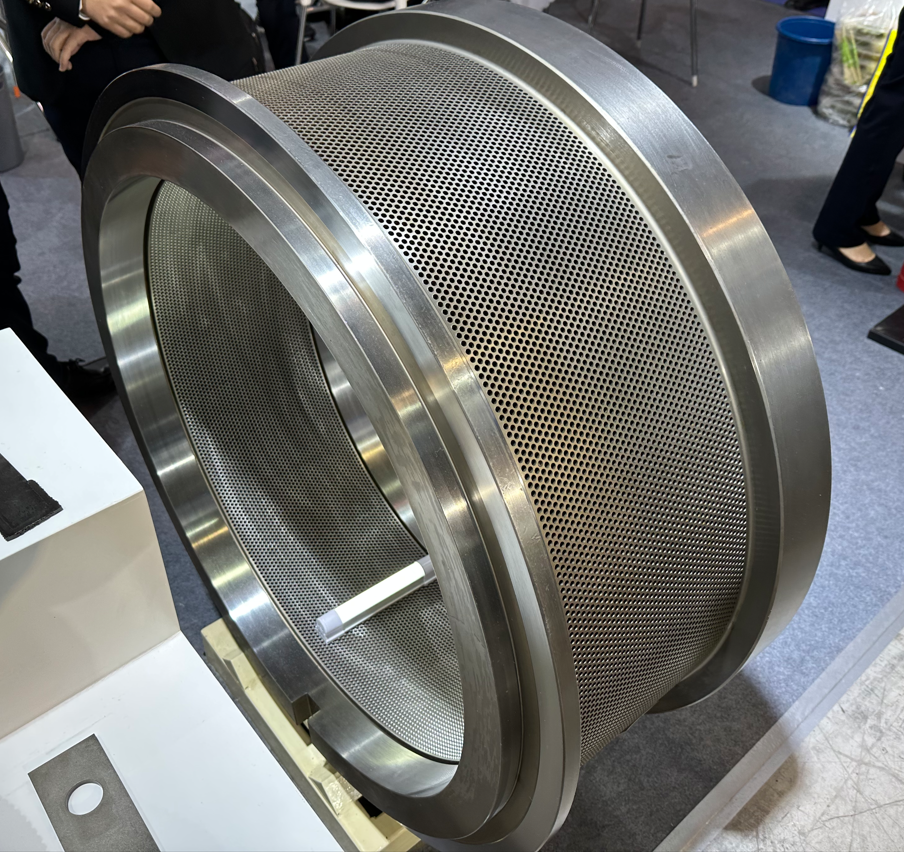

With the promotion and application of pellet feed in livestock and poultry, aquaculture industry, and emerging industries such as compound fertilizer, hops, chrysanthemum, wood chips, peanut shells, and cottonseed meal, more and more units use ring die pellet mills. Due to the diiferent of feed formula and regional differences, users have different requirements for pellet feed. Each feed manufacturer requires good pellet quality and the highest pelleting efficiency for the pellet feed it produces. Due to the different feed formulas, the selection of ring die parameters when pressing these pellet feeds is also different. The parameters are mainly reflected in the selection of material, pore diameter, pore shape, aspect ratio, and opening ratio. The selection of ring die parameters must be determined according to the chemical composition and physical properties of various raw materials that make up the feed formula. The chemical composition of raw materials mainly includes protein, starch, fat, cellulose, etc. The physical properties of raw materials mainly include particle size, moisture, capacity, etc.

Livestock and poultry feed mainly contains wheat and corn, with high starch content and low fiber content. It is a high-starch feed. To press this type of feed, it must ensure that the starch is fully gelatinized and meet the high temperature and processing conditions. The thickness of the ring die is generally thick, and the aperture The range is wide, and the aspect ratio is generally between 1 : 8-1 : 10 . Broiler chickens and ducks are high-energy feeds with high fat content, easy granulation, and relatively large half length and diameter between 1:13.

Aquatic feed mainly includes fish feed, shrimp feed, soft-shelled turtle feed, etc. Fish feed has a high crude fiber content, while shrimp feed and soft-shelled turtle feed have low crude fiber content and high protein content, which belong to high-protein feed. Aquatic materials require long-term stability of particles in water, consistent diameter and neat length, which requires fine particle size and high degree of ripening when the material is granulated, and pre-ripening and post-ripening processes are used. The diameter of the ring die used for fish feed is generally between 1.5-3.5 , and the aspect ratio range is generally between 1 : 10-1 : 12 . The aperture range of the ring die used for shrimp feed is between 1.5-2.5 , and the length-to-diameter ratio range is between 1:11-1:20 . The specific parameters of the length-to-diameter ratio are selected It must be determined according to the nutritional indicators in the formula and the requirements of users. At the same time, the design of the die hole shape does not use stepped holes as much as possible under the condition of strength permitting, so as to ensure that the cut particles are of uniform length and diameter.

The compound fertilizer formula mainly consists of inorganic fertilizer, organic fertilizer and minerals. Inorganic fertilizers in compound fertilizers such as urea are more corrosive to the ring die, while minerals are severely abrasive to the die hole and inner cone hole of the ring die, and the extrusion force is relatively high. big. The hole diameter of compound fertilizer ring die is generally large, ranging from 3 to 6. Due to the large wear coefficient, the die hole is difficult to discharge, so the length-to-diameter ratio is relatively small, generally between 1 :4-1 : 6 . The fertilizer contains bacteria, and the temperature should not exceed 50-60 degrees, otherwise it is easy to kill the bacteria. Therefore, the compound fertilizer requires a lower granulation temperature, and generally the wall thickness of the ring die is relatively thin. Due to the severe wear and tear of compound fertilizer on the ring die hole, the requirements on the hole diameter are not too strict. Generally, the ring die is scrapped when the gap between the pressure rollers cannot be adjusted. Therefore, the length of the stepped hole is used to ensure the aspect ratio and improve the final service life of the ring die.

The content of crude fiber in hops is high and contains strains, and the temperature generally cannot exceed 50 degrees, so the wall thickness of the ring die for pressing hops is relatively thin, and the length and diameter are relatively short, generally about 1:5 , and the particle diameter is larger at 5-6 between.

Chrysanthemum, peanut shells, cottonseed meal, and sawdust contain a large amount of crude fiber, the crude fiber content is more than 20% , the oil content is low, the friction resistance of the material passing through the die hole is large, the granulation performance is poor, and the hardness of the granules is required. Low, it is difficult to meet the requirements if it can be formed generally, the particle diameter is relatively large, generally between 6-8 , and the aspect ratio is generally about 1:4-1:6 . Because this type of feed has a small bulk density and a large diameter of the die hole, tape must be used to seal the outer circle of the die hole area before granulation, so that the material can be fully filled into the die hole and formed, and then the tape is torn off.

For the granulation of various materials, dogma cannot be rigidly followed. It is necessary to select the correct ring die parameters and operating conditions according to the granulation characteristics of the material and the specific characteristics of each feed manufacturer. Only by adapting to local conditions can high-quality feed be produced.

Cause Analysis and Improvement Method of Abnormal Particles

Feed production units often have abnormal pellets when producing feed, which affects the appearance and internal quality of the pellets, thus affecting the sales and reputation of the feed factory. The following is a list of reasons for the abnormal particles that often occur in feed mills and a list of suggested improvement methods:

| serial number | Shape features |

cause |

It is recommended to change |

|

1 |

There are many cracks on the outer side of the curved particle |

1. The cutter is too far away from the ring die and blunt 2. The powder is too thick 3. Feed hardness is too low |

1. Move the cutter and replace the blade 2. Improve the crushing fineness 3. Increase the effective length of the die hole 4. Add molasses or fat |

|

2 |

Horizontal transverse cracks appear |

1. The fiber is too long 2. The tempering time is too short 3. Excessive humidity |

1. Control fiber fineness 2. Extend the modulation time 3. Control the temperature of raw materials and reduce the moisture in tempering |

|

3 |

Particles produce vertical cracks |

1. The raw material is elastic, that is, it will expand after compression 2. Too much water, cracks appear when cooling 3. The residence time in the die hole is too short |

1. Improve formula and increase feed density 2. Use dry saturated steam for tempering 3. Increase the effective length of the die hole |

|

4 |

Radiation cracks from a source point | Unground large kernels (such as half or whole corn kernels) | Control the crushing fineness of raw materials and increase the uniformity of crushing |

|

5 |

The particle surface is uneven |

1. Inclusion of large-grained raw materials, insufficient tempering, unsoftened, protruding from the surface 2. There are bubbles in the steam, and after granulation, the bubbles burst and pits appear |

1. Control the crushing fineness of raw materials and increase the uniformity of crushing 2. Improve steam quality |

|

6 |

Whiskers | Too much steam, too much pressure, the particles leave the ring die and burst, making the fiber particle raw materials protrude from the surface and form whiskers |

1. Reduce steam pressure, use low-pressure steam ( 15- 20psi ) quenching and tempering 2. Pay attention to whether the position of the pressure reducing valve is accurate |

|

material type |

feed type |

Ring die aperture |

|

high starch feed |

Φ2-Φ6 |

|

|

Livestock pellets |

high energy feed |

Φ2-Φ6 |

|

Aquatic feed pellets |

high protein feed |

Φ1.5-Φ3.5 |

|

Compound Fertilizer Granules |

urea-containing feed |

Φ3-Φ6 |

|

hop pellets |

high fiber feed |

Φ5-Φ8 |

|

Chrysanthemum Granules |

high fiber feed |

Φ5-Φ8 |

|

Peanut Shell Granules |

high fiber feed |

Φ5-Φ8 |

|

Cottonseed Hull Granules |

high fiber feed |

Φ5-Φ8 |

|

Peat pellets |

high fiber feed |

Φ5-Φ8 |

|

wood pellets |

high fiber feed |

Φ5-Φ8 |