Factory Free sample Conditioner For Pellet Mill - Tear Circle Type Hammer MillMachine for Feed industry – Zhengyi

- SHH.ZHENGYI

Factory Free sample Conditioner For Pellet Mill - Tear Circle Type Hammer MillMachine for Feed industry – Zhengyi Detail:

Hammer mill for the grinding of pellet and powder raw material in feed., food, chemical industry. Brewing industry and so on.

The grinding chamber is the water-drop type and U-shaped second grinding mechanism is on the bottom of the grinding chamber which can effectively eliminate circumfluence and increase 25% throughput.

Rotor passes the dynamic balance testing and adopts imported SKF bearing with the advantages of low noise, long operating life, and little maintenance.

Feed pellet equipment: water drop crusher (pig feed crusher).

Product Description

As one of the commonly feed equipment, the water drop crusher is mainly used to crush raw materials into small particles or powder suitable for particle manufacturing. It has the following characteristics:

1. The crushing chamber is of true water-drop shape, and the air inlet mode can effectively avoid air circulation phenomenon in the crushing process; The U-shaped secondary striking groove is set high at the bottom of the crushing chamber to greatly improve the output. The fully open operation door and elastic screen pressing mechanism can greatly facilitate the maintenance and replacement of screen pieces.

2. Imported SKF bearings are used to ensure service life; The nylon-rod type coupling device is directly driven, which could compensate large displacement and effectively avoid bearing heating.

3. The rotor has been verified by dynamic balance to Ensure more balanced operation, lower noise, and better performance.

4. Through adjustment, coarse crushing, fine crushing, and micro crushing can be realized, so that one machine can be used for multiple purposes.

5. The feed inlet is on the top of the crusher and can be matched with various forms of feeding mechanisms.

6. It is mainly used for crushing various granular raw materials, such as corn, sorghum, wheat, beans, etc.

Parameter

| MODEL | POWER(KW) | CAPACITY(t/h) | FEEDER MODEL |

| SFSP300 | 55/75 | 8-12 | SWLY300 |

| SFSP400 | 75/90/110 | 12-20 | SWLY400 |

| SFSP600 | 132/160 | 20-30 | SWLY600 |

| SFSP800 | 200/220 | 30-42 | SWLY800 |

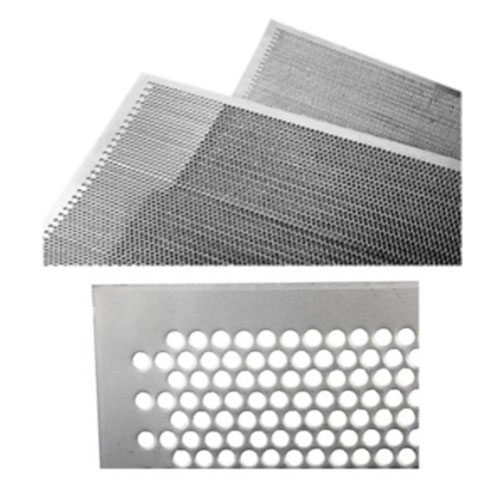

The spare parts for water drop hammer mills include:

1. ROTOR HAMMER TABLET

2. BEARING WITH THE BASE

3. SIEVE PLATE

4. GRINDING ROOM WITH MULTI-CHAMBER

Product detail pictures:

Related Product Guide:

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for Factory Free sample Conditioner For Pellet Mill - Tear Circle Type Hammer MillMachine for Feed industry – Zhengyi , The product will supply to all over the world, such as: Austria , Suriname , Austria , It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!