Good Quality Twin Screw Extruder - Best manufacturer of CPM Series Ring Die for Pellet mill spare parts – Zhengyi

- SHH.ZHENGYI

Good Quality Twin Screw Extruder - Best manufacturer of CPM Series Ring Die for Pellet mill spare parts – Zhengyi Detail:

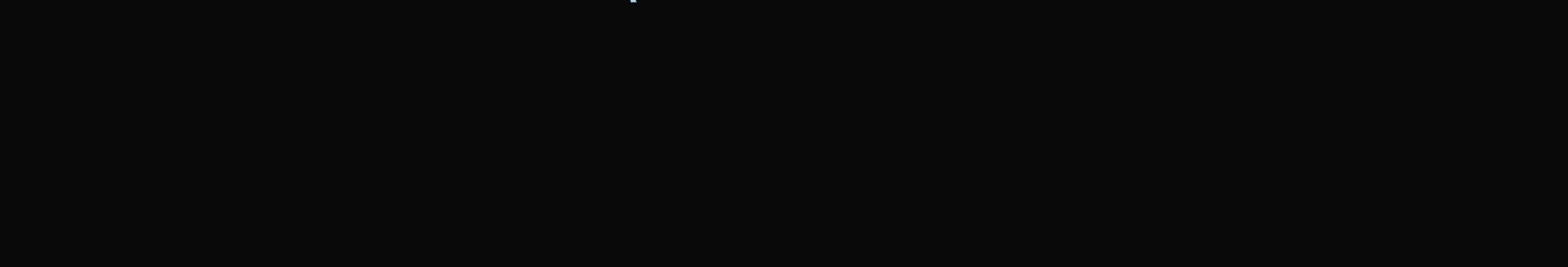

How many types of Drilling?

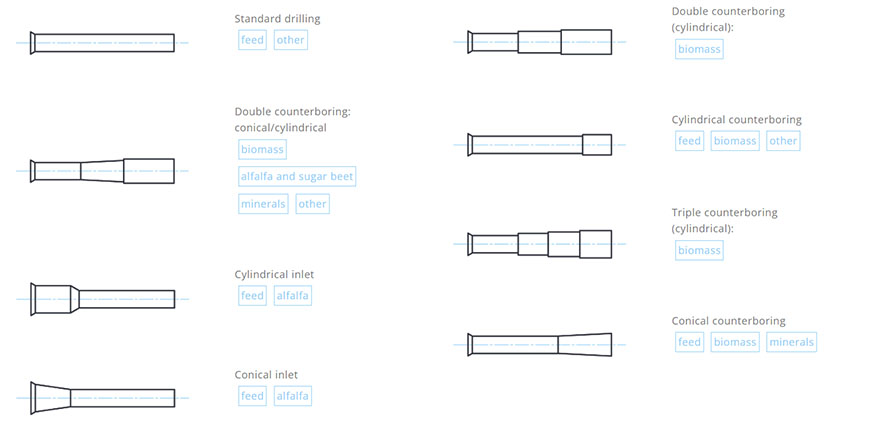

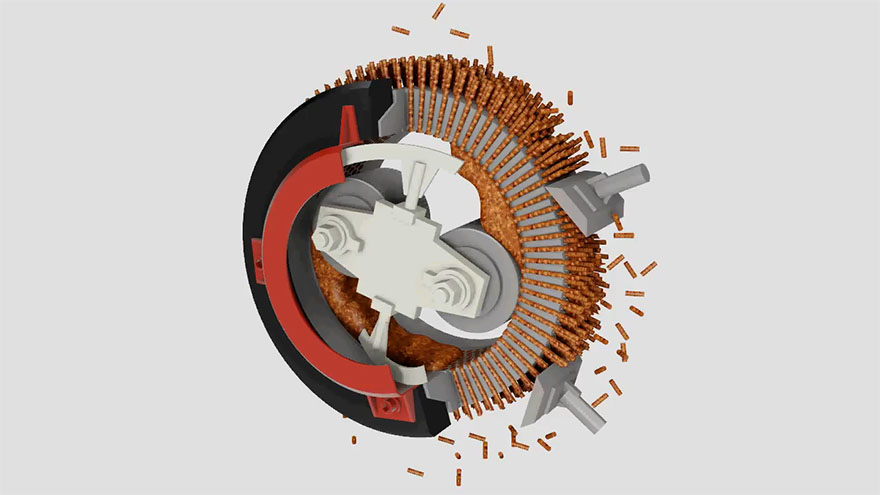

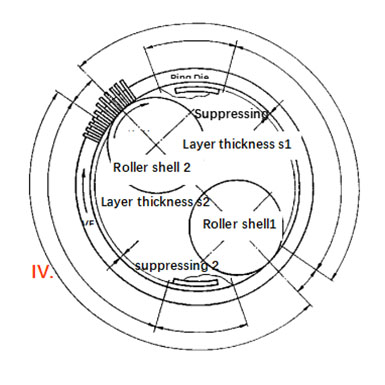

How does Ring Die works?

Why choose us?

No outsourcing, no OEM, industry-leading CNC deep hole gun drilling equipment and vacuum heat treatment equipment, imported from Germany processing supplies, high precision and short delivery time.

High-optimization European standard X46CR13 standard, the industry forgings benchmark Jinkun forging, direct mining industry leading brand Sanxin ingot, direct reading spectral metal material analysis, metal metallography, Brinell hardness, ultrasonic flaw detection of two-way testing force to ensure the quality of material.

High standard design standards, independent research and development of the ring mold design system, to ensure the ring mold design strength at the same time to bring high benefits to customers capacity and particle quality, more can be customized according to customer needs of special ring mold design, to create customer exclusive products.

There are 24 inspection items in the three inspection modules of raw material, process and shipment, and each procedure has its corresponding inspection items. The input of industry-leading inspection equipment and the whole quality report can be traced back.

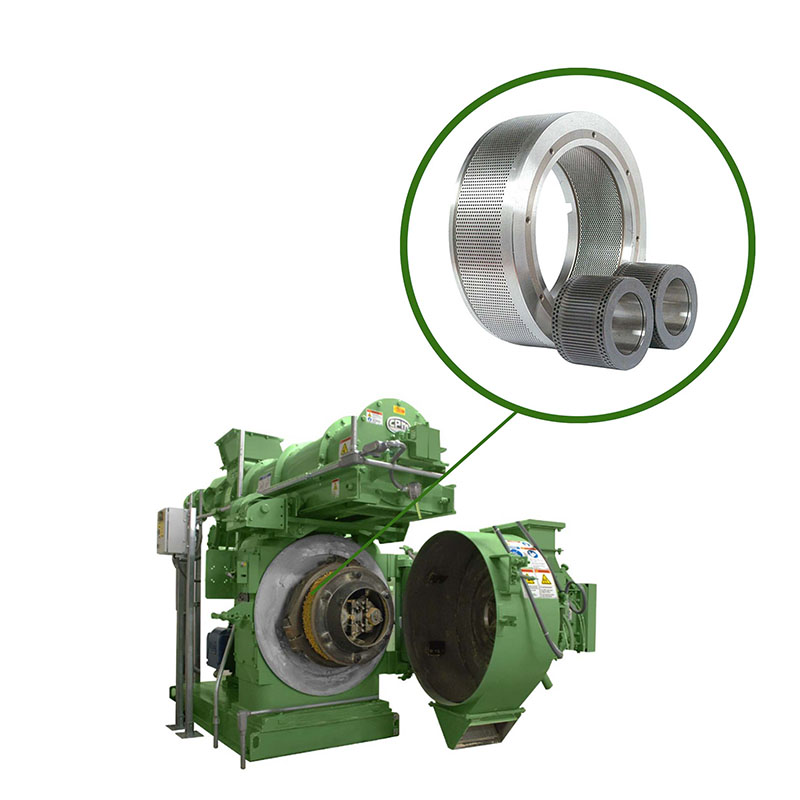

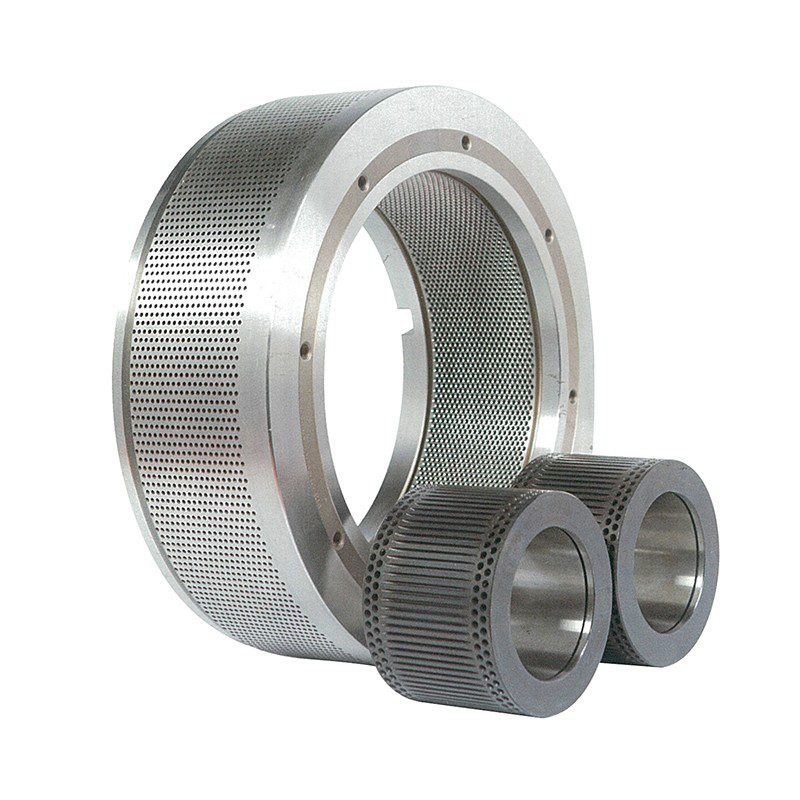

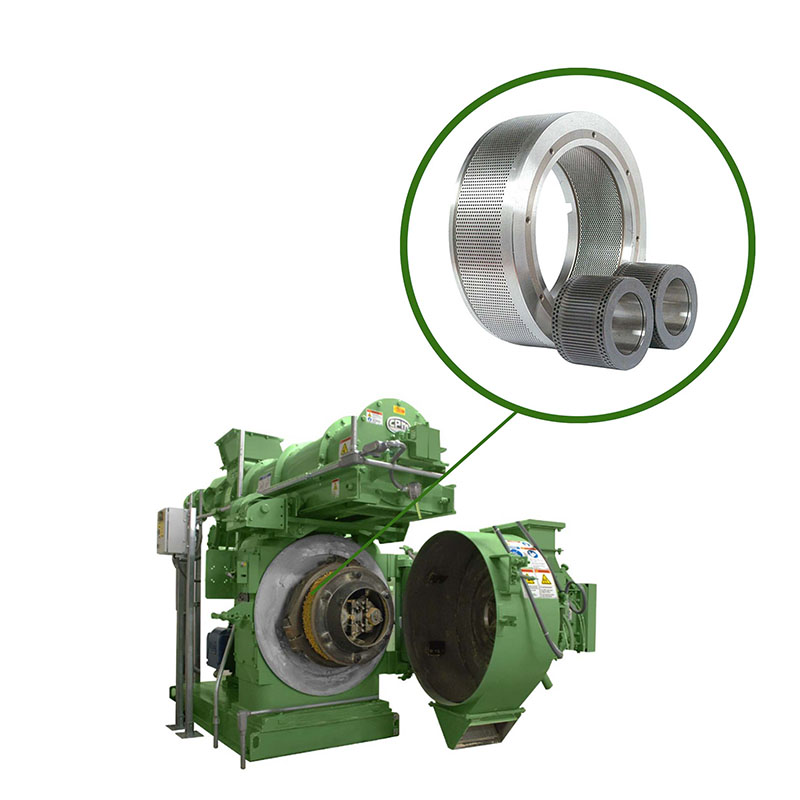

● CPM series ring die

CPM pellet mill series ring die is made of high-quality alloy steel or high-chromium stainless steel (German standard X46cr13). It is processed by forging, cutting, drilling, heat treatment and other processes. Through strict production management and quality system, the hardness, die hole uniformity and die hole finish of the production ring die have reached very high quality.

Parameter

| S/N | Model | Size OD*ID*overall width*pad width -mm | Hole size mm |

| 1 | CPM3016-4 | 559*406*190*116 | 1-12 |

| 2 | CPM3016-5 | 559*406*212*138 | 1-12 |

| 3 | CPM3020-6 | 660*508*238*155.5 | 1-12 |

| 4 | CPM3020-7 | 660*508*264*181 | 1-12 |

| 5 | CPM3022-6 | 775*572*270*155 | 1-12 |

| 6 | CPM3022-8 | 775*572*324.5*208 | 1-12 |

| 7 | CPM3026-6 | 890*673*325*180 | 1-12 |

| 8 | CPM3026-8 | 890*673*388*238 | 1-12 |

| 9 | CPM3032-9 | 1022.5*826.5*398*240 | 1-12 |

| 10 | CPM3032-11 | 1027*825*455.5*275 | 1-12 |

| 11 | CPM3032-12 | 1026.5*828.5*508*310.2 | 1-12 |

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Good Quality Twin Screw Extruder - Best manufacturer of CPM Series Ring Die for Pellet mill spare parts – Zhengyi , The product will supply to all over the world, such as: Morocco , New Zealand , Azerbaijan , The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.