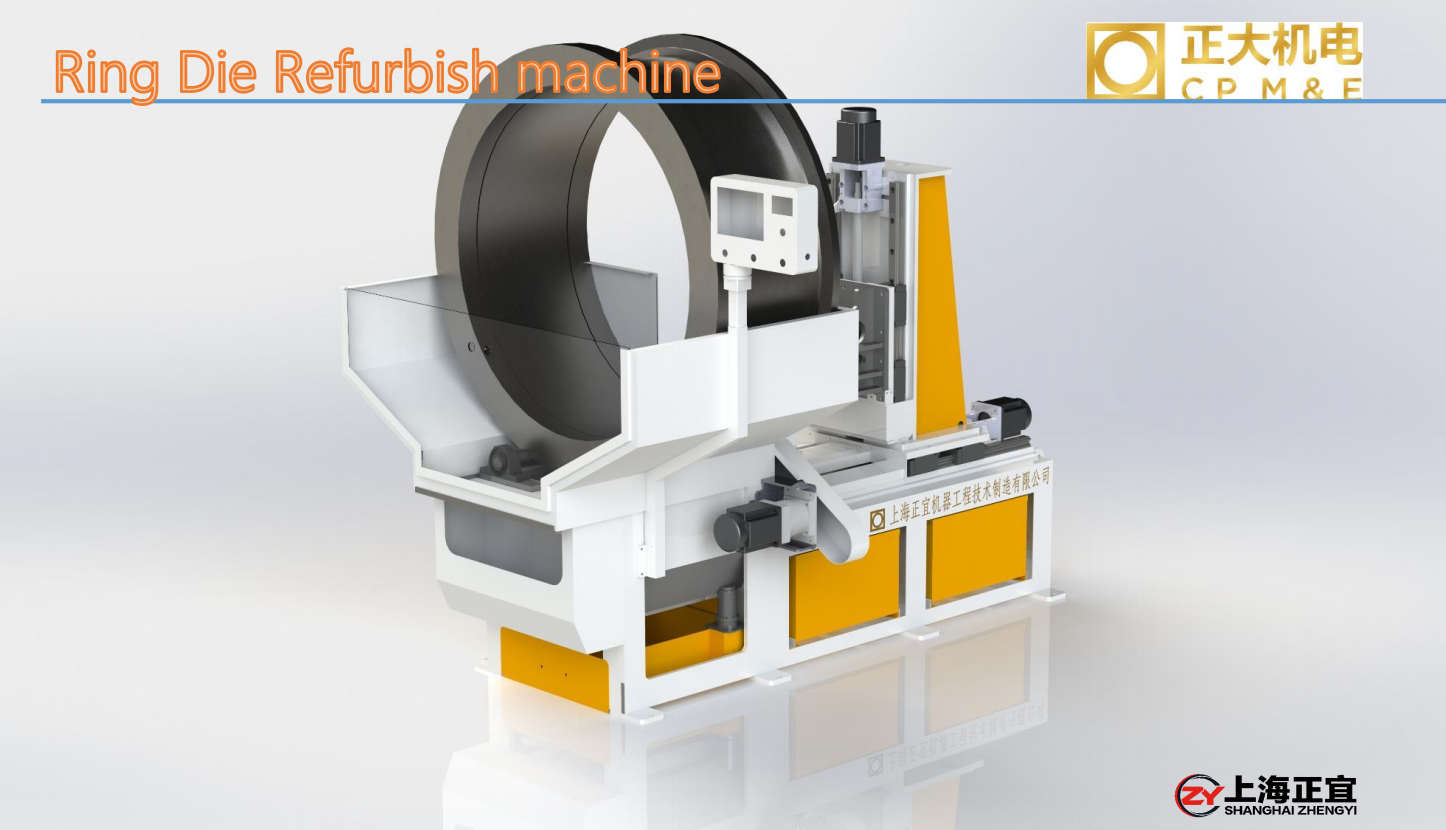

The operation steps of Shanghai Zhengyi’s pellet mill ring die repairing machine are as follows:

- Install the ring die: Hoist the ring die to be repaired to the work area, install it on the mold mounting bracket, adjust the positions of the driven wheel and positioning wheel and lock them, and move the detection sensor to a proper position. Start the continuous rotation button of the ring die, and after 2-3 rotations, press the parameter writing button to write the indexing parameters detected by the position detection sensor into the computer, then remove the detection sensor.

- Clean the ring die: Install a cleaning wire brush at the chuck of the CNC drilling machine, adjust the starting cleaning position, and set the parameters. Select the drilling mode on the control panel and press the start button. The drilling machine inverter starts at the preset speed, the drilling power head rotating motor drives the wire brush to rotate, and at the same time, the indexing servo motor starts and drives the ring die to rotate at the preset speed. After a 2-second delay, the left and right moving servo motor of the drilling machine starts, driving the drilling power head to move left and right, and starts to clean the residual feed on the inner and outer surfaces of the ring die and the rust on the left and right sides. After cleaning, the equipment will automatically return to the starting position and alarm, and the relevant motors will stop working.

- Grind the inner circular surface of the ring die: Install a grinding wheel on the CNC grinding machine, adjust the starting grinding position, and set the parameters. Select the grinding mode on the control panel and press the start button. The grinding machine inverter starts as preset, the grinding power head rotating motor drives the grinding wheel to rotate, and at the same time, the indexing servo motor starts to drive the ring die to rotate. After a 2-second delay, the left and right moving servo motor of the grinding machine starts, driving the grinding power head to move left and right, and starts to grind the inner circular surface of the ring die. After reaching the set grinding range, the equipment will automatically return to the starting position and alarm, and the relevant motors will stop working.

- Unclog the die holes: Install a hole cleaning drill bit at the chuck of the CNC drilling machine, set the parameters, select the drilling mode on the control panel, and adjust the appropriate height and hole position. Press the start button, the drilling machine inverter starts as preset, and the drilling power head rotating motor drives the hole cleaning drill bit to rotate. After a 2-second delay, the feeding servo motor of the drilling machine starts to move down according to the preset depth and starts to clean the first hole. After cleaning, return to the starting position. At the same time, the indexing servo motor starts and drives the ring die to rotate according to the preset number of holes, and rotates to the next hole position according to the set parameters to start cleaning the second hole. Repeat the above actions. After cleaning the first row, the indexing motor rotates half a hole distance, the left and right row feeding motors start and displace according to the preset row distance, and the drilling power head automatically dislocates to the specified position of the second row to continue hole cleaning until the hole cleaning of the entire ring die is completed. The equipment automatically returns to the starting position and alarms, and the relevant motors stop working.

- Chamfer the die holes: Install a chamfering drill bit on the CNC drilling machine, set the parameters, select the drilling mode on the control panel, and adjust the appropriate height. Press the start button, the drilling machine inverter starts at the preset speed, the drilling power head rotating motor drives the chamfering drill bit to rotate, and at the same time, the cooling water pump starts to supply cooling water. After a 2-second delay, the feeding servo motor of the drilling machine starts to move down according to the preset depth and starts to chamfer the first hole. After chamfering the first hole, return to the starting position. Then the indexing servo motor starts and drives the ring die to rotate to the next hole position according to the preset number of holes to start chamfering the second hole. Repeat the above actions. After chamfering the first row, automatically dislocate to the specified position of the second row to continue chamfering until the chamfering of the entire ring die is completed. The equipment automatically returns to the starting position and alarms, and the relevant motors stop working.

- Dismantle the ring die: After the above steps are completed, dismantle the ring die and clean the equipment, and the entire repair work is finished.

At present, no relevant operation videos of Shanghai Zhengyi’s pellet mill ring die repairing machine have been found. If you need more intuitive operation guidance, it is recommended to contact Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. for assistance.