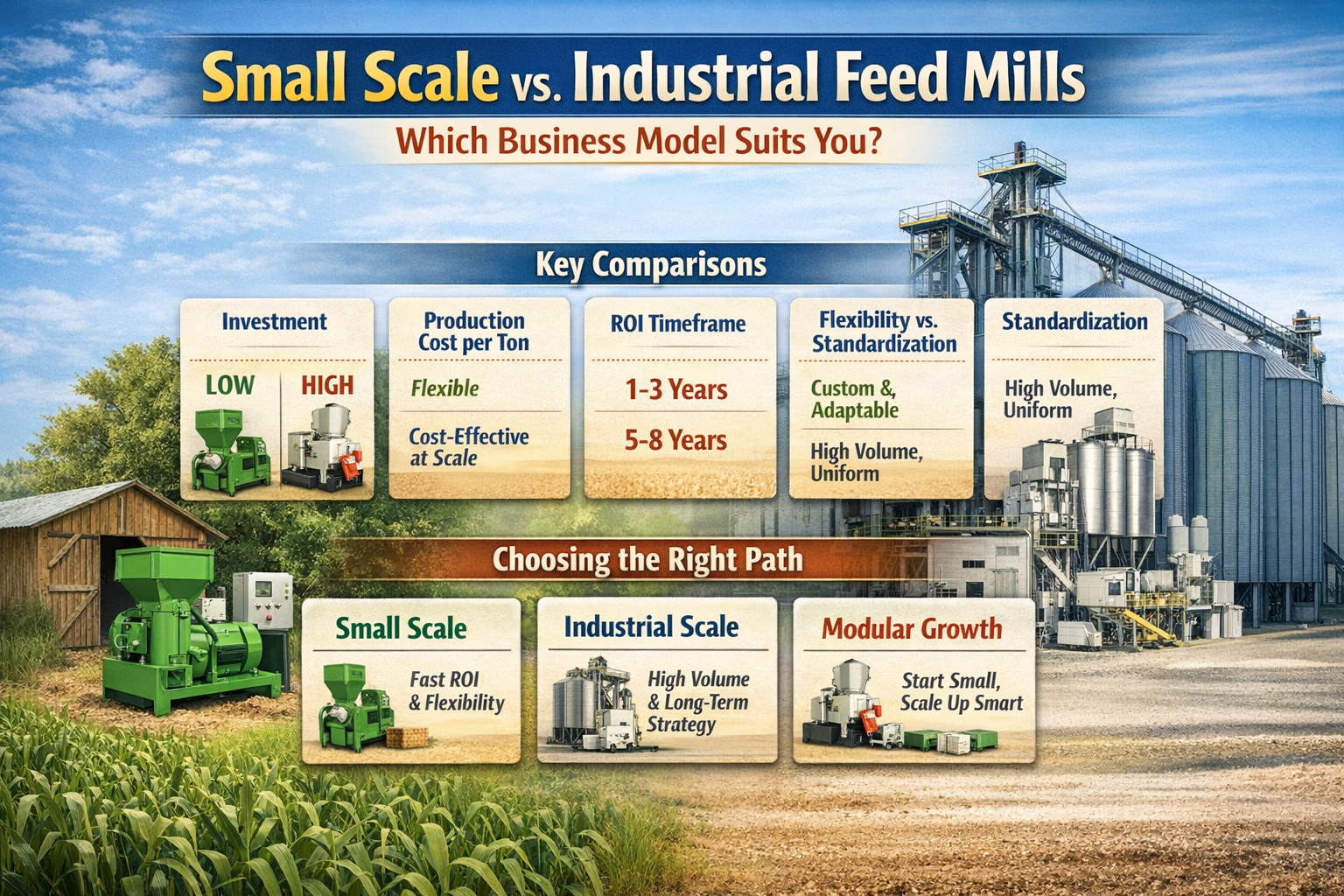

Small Scale vs. Industrial Feed Mills: Which Business Model Suits You?

Target Keywords: small scale vs industrial feed mill, farm pellet machine, feed manufacturing business plan

Industry Focus: Feed Manufacturing | Pellet Mill Engineering | Agribusiness Investment | Feed Plant ROI Analysis

Introduction: Why Choosing the Right Feed Mill Model Matters More Than Ever

In today’s increasingly competitive feed manufacturing landscape, the question is no longer whether to invest in feed production—but how to do it efficiently, profitably, and sustainably.

Rising raw material prices, tighter margins, growing demand for traceable nutrition, and increasing pressure to reduce production costs per ton have pushed many investors, farmers, and agribusiness owners to re-evaluate their feed manufacturing strategies.

At the center of this decision lies a critical comparison:

Small scale vs. industrial feed mill — which business model truly suits your operation?

Should you invest in a farm-use pellet machine designed for internal consumption and flexibility?

Or does a commercial-scale feed line offer better long-term ROI, scalability, and market competitiveness?

This article breaks down the problem, analyzes the technical and financial realities of both models, and provides a clear decision framework to help you build a feed manufacturing business plan that aligns with your goals.

Part 1: The Core Problem — One Industry, Two Very Different Paths

The Misconception: “Bigger Is Always Better”

A common assumption in feed manufacturing is that industrial-scale operations automatically deliver higher profitability. While large feed mills benefit from economies of scale, they also come with higher capital expenditure, operational complexity, and financial risk.

Conversely, small-scale feed production is often dismissed as inefficient or “non-commercial,” despite its growing adoption among progressive farms, cooperatives, and regional producers.

The real issue is not scale, but fit.

The wrong feed mill model—whether too small or too large—can lead to:

- l Underutilized capacity

- l Poor ROI

- l High energy cost per ton

- l Operational inefficiencies

- l Cash flow pressure

Understanding the fundamental differences between small scale vs industrial feed mills is the first step toward making a sound investment decision.

Part 2: Analysis — Technical & ROI Comparison Between Two Models

1. Defining the Two Feed Mill Models

Small Scale Feed Mill (Farm-Level Production)

Typically includes:

- l Farm pellet machine (200–2,000 kg/h)

- l Simple grinding + mixing + pelleting setup

- l Manual or semi-automatic operation

- l Designed for on-farm or local use

Primary users:

l Livestock & poultry farms

- l Aquaculture farms

- l Feed cooperatives

- l Emerging markets

- l Pilot feed businesses

Industrial Feed Mill (Commercial Production)

Typically includes:

- l Full automated feed production line (5–30+ TPH)

- l Advanced conditioning & pelleting systems

- l Centralized control (PLC / SCADA)

- l Continuous, high-volume operation

Primary users:

- l Commercial feed manufacturers

- l Export-oriented producers

- l Integrated agribusiness groups

- l Contract feed suppliers

2. Capital Investment & Entry Barriers

|

Item |

Small Scale Feed Mill |

Industrial Feed Mill |

|

Initial Investment |

Low |

Very High |

|

Installation Time |

Short |

Long |

|

Financing Risk |

Low |

High |

|

Infrastructure Demand |

Minimal |

Extensive |

A farm pellet machine allows feed production to start with limited capital, making it ideal for first-time investors or farms aiming to reduce external feed dependency.

In contrast, industrial feed mills require:

- l Large land area

- l Power infrastructure upgrades

- l Skilled technical teams

- l Long commissioning periods

3. Production Cost per Ton: The Hidden Truth

At first glance, industrial feed mills appear to have lower production costs due to scale. However, this advantage only materializes when capacity utilization exceeds 70–80%.

For underutilized plants:

- l Fixed costs inflate cost per ton

- l Energy inefficiencies increase

- l ROI period extends significantly

Small-scale feed mills, while having slightly higher unit energy consumption, often achieve:

- l Higher utilization rates

- l Lower fixed overhead

- l Faster breakeven cycles

Key Insight:

ROI is driven by capacity utilization, not installed capacity.

4. Energy Efficiency & Operational Complexity

Energy consumption represents 25–35% of feed production cost per ton.

- l Industrial feed mills benefit from optimized systems—but only when operated continuously.

- l Small-scale feed mills offer flexibility:

- l Run only when needed

- l Avoid idle energy losses

- l Simplified maintenance

For farms producing feed primarily for internal use, energy optimization through right-sized equipment often delivers better financial results than oversized systems.

5. Flexibility vs. Standardization

|

Factor |

Small Scale |

Industrial |

|

Formula Change |

Fast |

Slow |

|

Batch Customization |

Easy |

Limited |

|

Raw Material Variability |

High tolerance |

Requires consistency |

|

Market Response Speed |

Fast |

Moderate |

Industrial feed mills excel in standardized, high-volume production.

Small-scale systems excel in custom feed formulations, seasonal adjustments, and niche markets.

6. ROI Comparison: Time to Profitability

|

Metric |

Small Scale Feed Mill |

Industrial Feed Mill |

|

Typical ROI Period |

1–3 years |

5–8 years |

|

Cash Flow Risk |

Low |

High |

|

Expansion Strategy |

Modular |

Capital intensive |

For many investors, especially in developing markets or farm-based operations, shorter ROI cycles are often more valuable than long-term scale advantages.

Part 3: Solution — Choosing the Right Business Model for Your Feed Manufacturing Plan

Step 1: Clarify Your Business Objective

- l Ask yourself:

- l Is feed production for internal consumption or commercial sales?

- l Do you serve a local niche or a regional market?

- l Is flexibility or volume more important?

Step 2: Align Equipment with Demand, Not Ambition

One of the most common mistakes in feed manufacturing business plans is overestimating demand.

A properly sized farm pellet machine often delivers:

- l Faster payback

- l Easier management

- l Scalable growth

- l Industrial feed lines should only be considered when:

- l Market demand is proven

- l Sales channels are secured

- l Raw material supply is stable

Step 3: Build Scalability into the Plan

The smartest feed businesses don’t choose between small or industrial—they start small and scale intelligently.

A modular approach allows:

- l Initial investment control

- l Gradual capacity expansion

- l Risk-managed growth path

Many successful industrial feed producers today began with small-scale systems and expanded based on real market data.

Conclusion: The Best Feed Mill Is the One That Fits Your Reality

The debate around small scale vs industrial feed mill is not about which model is superior—but which one aligns with your operational reality, financial capacity, and market strategy.

- l Choose small scale if your priority is flexibility, fast ROI, and controlled risk.

- l Choose industrial scale if you have secured demand, strong financing, and long-term volume strategy.

- l Choose modular growth if you want the best of both worlds.

A successful feed manufacturing business plan is built on engineering logic, financial discipline, and realistic market assumptions—not on scale alone.

By selecting the right feed mill model at the right stage, you don’t just produce feed—you build a resilient, profitable business.