Target Keywords: feed production cost per ton, feed mill energy efficiency, reduce operating costs

Industry Focus: Feed Manufacturing | Pellet Mill Operations | Feed Plant Engineering

Introduction: Why Energy Efficiency Defines Feed Mill Competitiveness

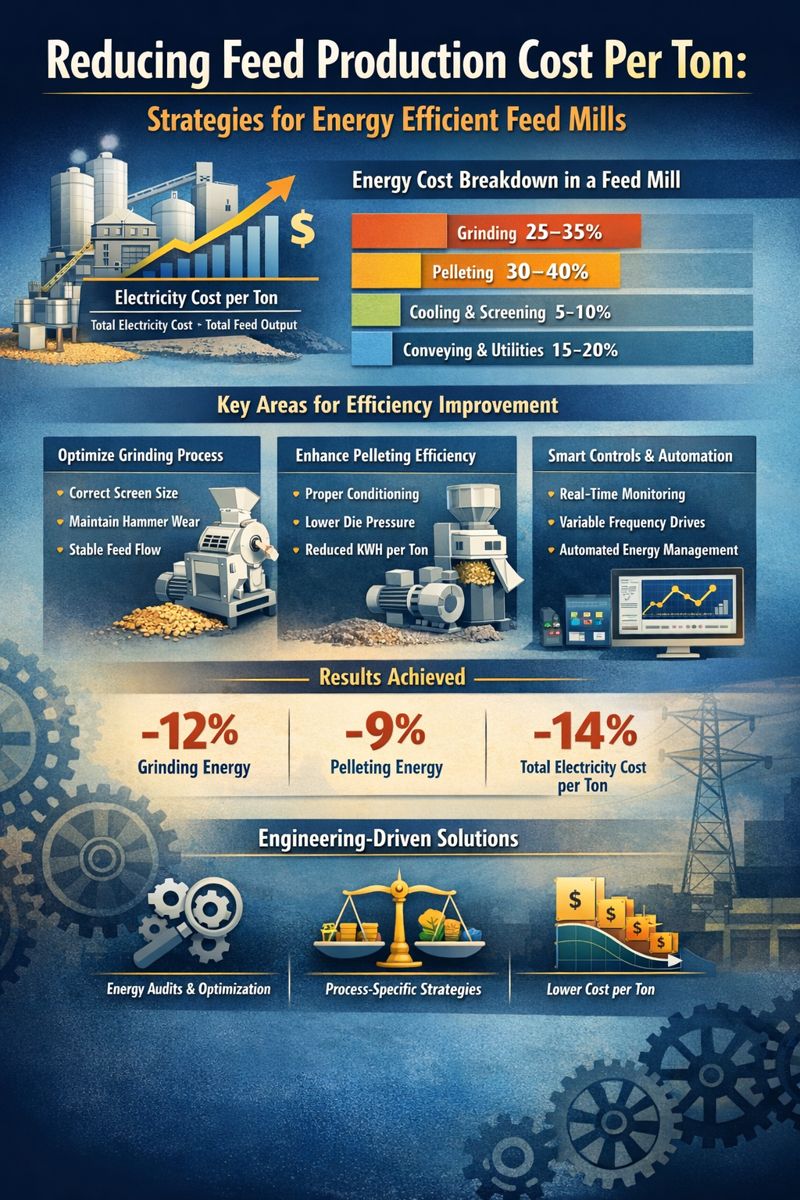

In modern feed manufacturing, operational cost control is no longer a back-office exercise—it is a core competitive strategy. Among all operating expenses (OPEX), energy consumption consistently accounts for 25–35% of total feed production costs per ton, making it the single largest controllable cost factor in most feed mills.

As electricity prices rise globally and sustainability regulations tighten, feed producers are under increasing pressure to improve feed mill energy efficiency without compromising throughput, pellet quality, or equipment lifespan. The key question is no longer whether energy efficiency matters, but how systematically it can be improved.

This article provides a professional, engineering-based analysis of energy consumption in feed production, identifies major energy-intensive processes, and presents proven strategies to reduce operating costs per ton—backed by real-world plant optimization experience.

Understanding Energy Consumption in Feed Production

Typical Energy Cost Structure in a Feed Mill

Energy consumption in a feed plant is distributed across several key processing stages:

|

Process Section |

Share of Total Energy Consumption |

|

Grinding (Hammer Mill) |

25–35% |

|

Conditioning & Pelleting |

30–40% |

|

Cooling & Screening |

5–10% |

|

Conveying & Auxiliary Systems |

10–15% |

|

Dust Collection & Utilities |

5–10% |

While exact figures vary depending on raw materials, plant layout, and production scale, grinding and pelleting together typically consume over 60% of total electricity. Therefore, meaningful cost reduction must start here.

Key Metric: Electricity Cost per Ton

Rather than focusing solely on total power consumption, professional feed producers monitor a more actionable KPI:

Electricity Cost per Ton = Total Electricity Cost ÷ Total Feed Output (tons)

This metric allows meaningful comparison across:

- l Different production shifts

- l Different feed formulations

- l Different equipment configurations

- l A well-optimized feed mill typically achieves:

- l Grinding: 10–18 kWh/ton

- l Pelleting: 15–25 kWh/ton

- l Total Plant: 35–55 kWh/ton

Plants operating significantly above these ranges often suffer from hidden inefficiencies rather than unavoidable design limits.

Grinding Efficiency: Where Energy Is Often Wasted

Common Causes of High Grinding Energy Consumption

Hammer mills are frequently oversized, poorly adjusted, or operated far from their optimal load point. The most common issues include:

- l Incorrect screen hole diameter

- l Excessive hammer wear

- l Low material flow stability

- l Over-fine grinding beyond formulation requirements

Each of these factors increases kWh per ton without improving feed performance.

Optimization Strategies

- l Match Particle Size to Animal Needs

- Grinding finer than necessary increases power consumption exponentially while offering diminishing nutritional returns.

- l Optimize Hammer Configuration

- Proper hammer arrangement and timely replacement reduce impact losses and improve throughput.

- l Maintain Stable Feed Flow

- Variable feed rate causes current spikes and inefficient motor loading.

A 10–15% reduction in grinding energy is commonly achievable through mechanical and operational optimization alone.

Pelleting: Energy Efficiency Beyond Pressure

The Myth: Higher Pressure Equals Better Pellets

Many operators instinctively increase pelleting pressure to improve pellet durability. In practice, this approach often leads to:

- l Higher motor load

- l Accelerated die and roller wear

- l Increased power consumption per ton

- l Higher maintenance costs

- l Pellet quality should be engineered, not forced.

Conditioning Quality Is the Real Lever

Efficient pelleting depends heavily on conditioning performance:

- l Adequate moisture addition

- l Uniform heat transfer

- l Sufficient retention time

- l Well-conditioned mash reduces mechanical resistance in the die, allowing:

- l Lower main motor load

- l Improved pellet quality

- l Reduced kWh per ton

Optimized conditioning alone can reduce pelleting energy consumption by 8–12%.

Cooling and Its Hidden Energy Impact

Although coolers consume relatively little electricity directly, improper cooling indirectly increases energy costs by:

- l Causing pellet cracks and fines

- l Increasing reprocessing rates

- l Destabilizing downstream conveying

Excessive airflow and rapid temperature drop create internal pellet stress, leading to quality losses that translate into higher effective production costs.

- l Energy-efficient cooling focuses on:

- l Controlled airflow

- l Uniform temperature reduction

- l Stable discharge moisture

Auxiliary Systems: Small Loads, Big Opportunities

Conveying and Dust Collection

Auxiliary systems are often overlooked because individual motors are small. However, collectively they represent a significant energy draw.

Common inefficiencies include:

- l Continuous operation during idle periods

- l Poorly designed ducting with high pressure loss

- l Oversized fans running without frequency control

Variable Frequency Drives (VFDs)

Installing VFDs on:

- l Conveyors

- l Fans

- l Airlocks

allows power consumption to scale with actual demand. In many retrofit projects, payback periods are under 18 months.

Automation and Data-Driven Energy Control

From Manual Operation to Intelligent Control

Advanced feed mills increasingly integrate:

- l Real-time power monitoring

- l Load-based motor control

- l Energy dashboards linked to production data

This enables operators to identify:

- l Abnormal energy spikes

- l Equipment inefficiencies

- l Process bottlenecks

Energy transparency turns electricity from a fixed cost into a manageable variable.

Maintenance: The Silent Energy Multiplier

Poor mechanical condition increases energy consumption long before failure occurs.

Typical examples include:

- l Bearing wear increasing friction

- l Misaligned couplings causing vibration

- l Roller imbalance raising pelleting resistance

A preventive maintenance program focused on energy-related wear indicators can reduce total plant energy consumption by 5–10% annually.

Case Insight: Energy Cost Reduction per Ton

In a mid-scale poultry feed mill (10 T/H), a structured energy optimization program achieved:

- l 12% reduction in grinding energy

- l 9% reduction in pelleting energy

- l 18% reduction in auxiliary system consumption

Total electricity cost per ton dropped by 14%, with no capital-intensive equipment replacement.

Sustainability and Commercial Advantage

Energy efficiency is no longer only about cost reduction. It directly supports:

- l Carbon footprint reduction

- l ESG reporting requirements

- l Customer and investor confidence

Feed producers who proactively improve energy performance position themselves as technically advanced and operationally resilient partners.

Conclusion: Turning Energy Efficiency into a Strategic Asset

Reducing operating costs in feed production is not achieved through isolated adjustments, but through system-level efficiency engineering.

By focusing on:

- l Electricity cost per ton

- l Process-specific optimization

- l Data-driven control

feed mills can significantly reduce operating costs while improving product consistency and equipment longevity.

Energy efficiency is not a constraint—it is a competitive advantage waiting to be unlocked.

Why Work with an Engineering-Driven Feed Mill Partner

Reducing energy consumption in feed production requires more than isolated equipment upgrades—it demands a process-level understanding of how raw materials, machinery, and operating parameters interact.

Unlike generic equipment suppliers, an engineering-driven feed mill partner focuses on:

- l Process diagnostics, not assumptions

Energy losses are identified through load analysis, kWh/ton benchmarking, and bottleneck evaluation—not guesswork.

- l Application-specific solutions

Optimization strategies are tailored to poultry, livestock, or aqua feed formulations, taking into account raw material behavior and pellet quality targets.

- l Balanced performance improvement

Lower energy consumption is achieved without sacrificing throughput, pellet durability, or equipment lifespan.

- l Lifecycle cost perspective

Decisions are based on total cost of ownership (TCO), combining energy savings, wear reduction, and maintenance optimization.

Our engineering team works closely with feed producers to transform energy efficiency from a cost-control exercise into a long-term operational advantage.

From Energy Analysis to Measurable Cost Reduction

Every feed mill has a unique energy profile. Through structured audits and process optimization programs, feed producers can typically achieve:

- l 8–15% reduction in electricity cost per ton

- l Improved process stability and repeatability

- l Lower unplanned downtime caused by mechanical stress

- l Enhanced competitiveness in increasingly cost-sensitive markets

Energy efficiency is not a one-time project—it is a continuous improvement discipline.

Interested in reducing your feed production cost per ton?

Our engineering team specializes in feed mill energy audits, process optimization, and turnkey efficiency upgrades. Contact us to discuss how a data-driven approach can help your plant achieve sustainable cost savings and operational excellence.