A Practical Investment Guide for Feed Producers

Keywords: poultry feed mill cost, feed plant investment breakdown, turnkey project price

Industry: Poultry Feed Processing | Feed Mill Engineering | Turnkey Feed Plant Solutions

Introduction: Why Cost Transparency Matters in Feed Plant Investment

As global poultry production continues to expand, small and medium-scale feed producers are increasingly looking to invest in 1–10 tons per hour (T/H) poultry feed plants. However, one of the most frequently asked—and often misunderstood—questions remains:

“How much does it really cost to build a poultry feed mill?”

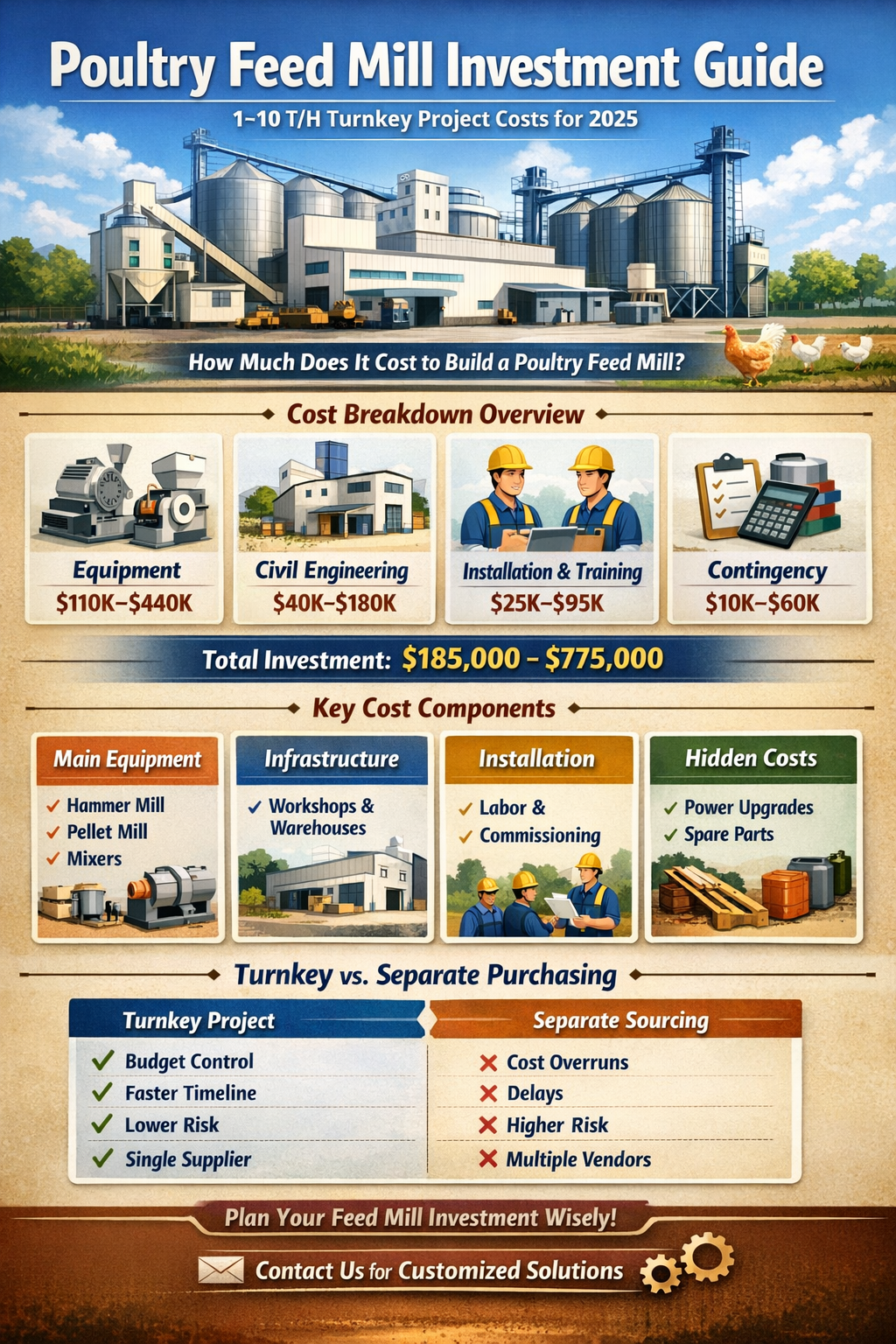

In 2025, rising raw material prices, energy costs, and labor expenses have made accurate feed plant investment planning more critical than ever. A realistic and transparent poultry feed mill cost breakdown helps investors avoid under-budgeting, reduce financial risk, and ensure long-term operational stability.

This article provides a comprehensive, engineering-based cost analysis for setting up a 1–10 T/H poultry feed plant, covering:

- l Equipment investment

- l Civil engineering costs

- l Installation and commissioning

- l Hidden expenses often overlooked

The goal is not only to present numbers—but to help you make informed, profitable decisions.

1. Overview: What Defines a 1–10 T/H Poultry Feed Plant?

A 1–10 T/H poultry feed plant typically serves:

- l Local or regional poultry farms

- l Integrated poultry producers

- l Commercial feed suppliers entering new markets

- Raw material receiving & storage

- Grinding (hammer mill)

- Batching & mixing

Typical Process Flow:

- l Pelletizing (optional but common)

- l Cooling, crumbling, screening

- l Packing & storage

The final investment varies significantly depending on:

- l Mash feed vs. pelleted feed

- l Automation level

- l Local construction standards

- l Turnkey vs. fragmented sourcing

2. Core Equipment Cost Breakdown (1–10 T/H)

Equipment investment usually represents 55–70% of the total poultry feed mill cost.

2.1 Main Processing Equipment

|

Equipment |

Cost Range (USD) |

|

Hammer Mill |

8,000 – 35,000 |

|

Feed Mixer (Single / Double Shaft) |

12,000 – 60,000 |

|

Pellet Mill (Ring Die) |

35,000 – 150,000 |

|

Cooler & Crumbler |

15,000 – 55,000 |

|

Screening System |

5,000 – 20,000 |

- l Estimated subtotal:

- USD 75,000 – 320,000

- l Engineering Note:

Choosing a double shaft paddle mixer improves feed homogeneity and reduces CV values, which directly enhances pellet quality and customer satisfaction.

2.2 Auxiliary Equipment & Automation

|

Item |

Cost Range (USD) |

|

Bucket Elevators & Conveyors |

10,000 – 50,000 |

|

Control System (PLC / Semi-auto) |

8,000 – 45,000 |

|

Liquid Addition System |

6,000 – 25,000 |

|

Dust Collection System |

5,000 – 30,000 |

l Estimated subtotal:

USD 30,000 – 120,000

✅ Equipment Investment Summary

For a 1–10 T/H poultry feed plant, total equipment cost typically ranges between:

USD 110,000 – 440,000

This wide range reflects different capacity levels, configurations, and automation requirements.

3. Civil Engineering & Infrastructure Costs

Civil works are often underestimated but are non-negotiable for safe and stable operation.

3.1 Key Civil Components

- l Workshop and equipment foundation

- l Raw material & finished feed warehouses

- l Electrical room and control room

- l Access roads and drainage

3.2 Cost Reference (2025)

|

Capacity |

Civil Cost (USD) |

|

1–3 T/H |

40,000 – 90,000 |

|

5–10 T/H |

80,000 – 180,000 |

�� Tip:

Steel structure buildings can reduce construction time and improve future expansion flexibility.

4. Installation, Commissioning & Training

A professional feed plant is not just installed, but engineered, aligned, and tested.

4.1 Installation Cost Components

- l Mechanical installation

- l Electrical wiring & control integration

- l On-site commissioning

- l Operator training

4.2 Typical Cost Range

|

Item |

Cost (USD) |

|

Installation Labor |

15,000 – 60,000 |

|

Commissioning & Testing |

5,000 – 25,000 |

|

Training & Documentation |

3,000 – 10,000 |

Total installation-related cost:

�� USD 25,000 – 95,000

5. Hidden & Often Overlooked Costs

Many projects exceed budget due to unplanned expenses, such as:

- l Power transformer & electrical upgrades

- l Spare parts & die sets

- l Local certification & compliance

- l Logistics, customs, inland transportation

- l Initial working capital

�� Recommended contingency:

5–10% of total feed plant investment

6. Total Poultry Feed Mill Cost Summary (2025)

|

Item |

Estimated Cost (USD) |

|

Equipment |

110,000 – 440,000 |

|

Civil Engineering |

40,000 – 180,000 |

|

Installation & Commissioning |

25,000 – 95,000 |

|

Contingency |

10,000 – 60,000 |

✅ Total Investment Range:

USD 185,000 – 775,000

This represents a realistic turnkey project price for a 1–10 T/H poultry feed plant in 2025.

7. Turnkey Project vs. Separate Purchasing: Which Is Better?

|

Aspect |

Turnkey Project |

Separate Sourcing |

|

Budget Control |

High |

Low |

|

Project Timeline |

Shorter |

Longer |

|

Technical Risk |

Lower |

Higher |

|

Long-term Stability |

Better |

Inconsistent |

For most investors—especially first-time feed producers—a turnkey feed plant solution offers better ROI and fewer operational risks.

8. How to Optimize Your Feed Plant Investment

To control poultry feed mill cost without compromising quality:

- l Match capacity to real production demand

- l Avoid over-automation in early stages

- l Prioritize mixer and pellet mill quality

- l Work with experienced feed engineering suppliers

- l Plan for future expansion during layout design

Conclusion: Invest Smart, Not Blindly

Setting up a 1–10 T/H poultry feed plant is a strategic investment—not a simple equipment purchase. A well-structured feed plant investment breakdown helps you:

- l Control capital expenditure

- l Reduce startup risks

- l Achieve stable feed quality

- l Improve long-term profitability

With proper engineering design, realistic budgeting, and a reliable equipment partner, a poultry feed mill can become a high-return, sustainable asset in 2025 and beyond.

�� Looking for a Customized Poultry Feed Plant Solution?

If you are planning to build or upgrade a poultry feed plant and need:

- l Accurate cost estimation

- l Turnkey project pricing

- l Process design & layout support

�� Contact our engineering team today for a tailored solution based on your production goals, local conditions, and budget expectations.