Revolutionizing Food Processing with the Best Extruder Technology and Applications

Table of Contents

- Advantages of Cutting-Edge Extruder Technology in Food Processing

- Key Technical Parameters of High-Performance Extruders

- Innovative Applications of Extruder Technology in the Food Industry

- Step-by-Step Guide to Selecting the Right Extruder for Your Needs

- Future Trends in Extrusion Technology and Food Processing

- Case Studies: Successful Implementations of Extruder Technology

- FAQS

- Related Posts

In recent years, the food processing industry has undergone a significant transformation, driven by advancements in technology and increasing consumer demand for sustainable practices. As outlined in the 2025 industry technology trends report, extrusion technology stands out as a pivotal innovation, enhancing the efficiency and quality of food products. The global extruder market is projected to grow at a CAGR of 5.2%, reaching USD 3.1 billion by 2025.

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY) leverages over 25 years of expertise in manufacturing feed processing machinery and producing high-quality pellet mill dies to meet this burgeoning demand. By integrating state-of-the-art extruder technology, CPSHZY not only offers comprehensive solutions for feed plants and aquaculture farms but also contributes to the development of environmentally friendly systems that align with contemporary sustainability goals.

Advantages of Cutting-Edge Extruder Technology in Food Processing

The food processing industry is experiencing a transformative shift, largely driven by advancements in extruder technology. Cutting-edge extruders are not only enhancing the efficiency of food production but also significantly improving product quality. According to a report by Mordor Intelligence, the global extruded snacks market is projected to grow at a CAGR of 6.5% from 2021 to 2026, highlighting the increasing demand for innovative food processing methods. These state-of-the-art machines allow manufacturers to achieve precise control over texture, moisture, and flavor, resulting in products that are not only appealing but also meet consumer health standards.

One of the primary advantages of utilizing modern extruder technology is its ability to streamline production processes. This equipment can handle a variety of raw materials, providing versatility in creating different food items—from gluten-free snacks to protein-enriched cereals. A study from Research and Markets indicates that 45% of consumers are actively seeking healthier snack options, which is pushing food manufacturers to adopt sophisticated production techniques that can cater to this trend efficiently. With continuous advancements in extruder designs, the future of food processing looks promising, offering producers an avenue to innovate and meet the evolving demands of the global market.

Advantages of Cutting-Edge Extruder Technology in Food Processing

This chart illustrates the key advantages of advanced extruder technology in food processing, showcasing the effectiveness in various categories.

Key Technical Parameters of High-Performance Extruders

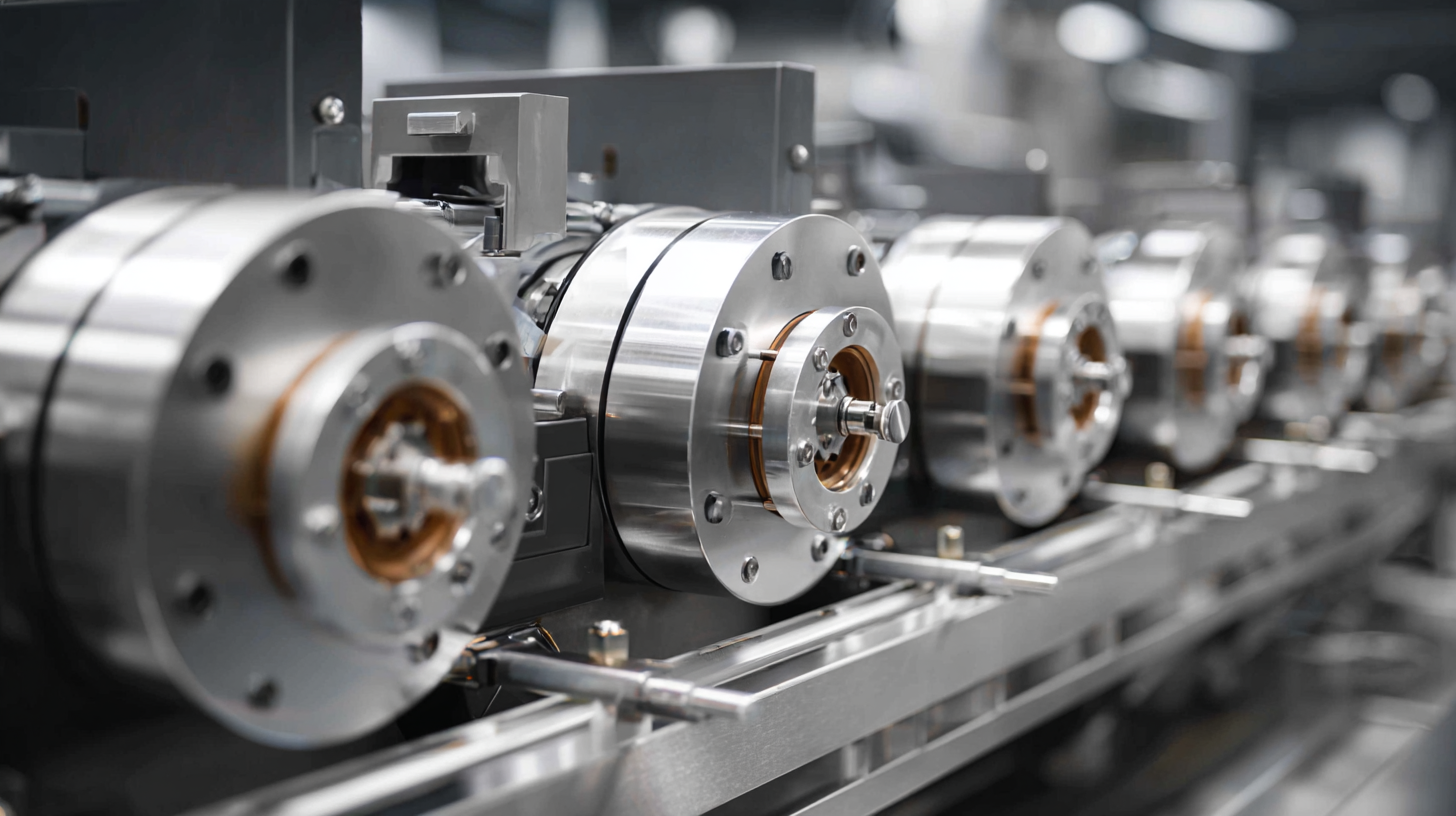

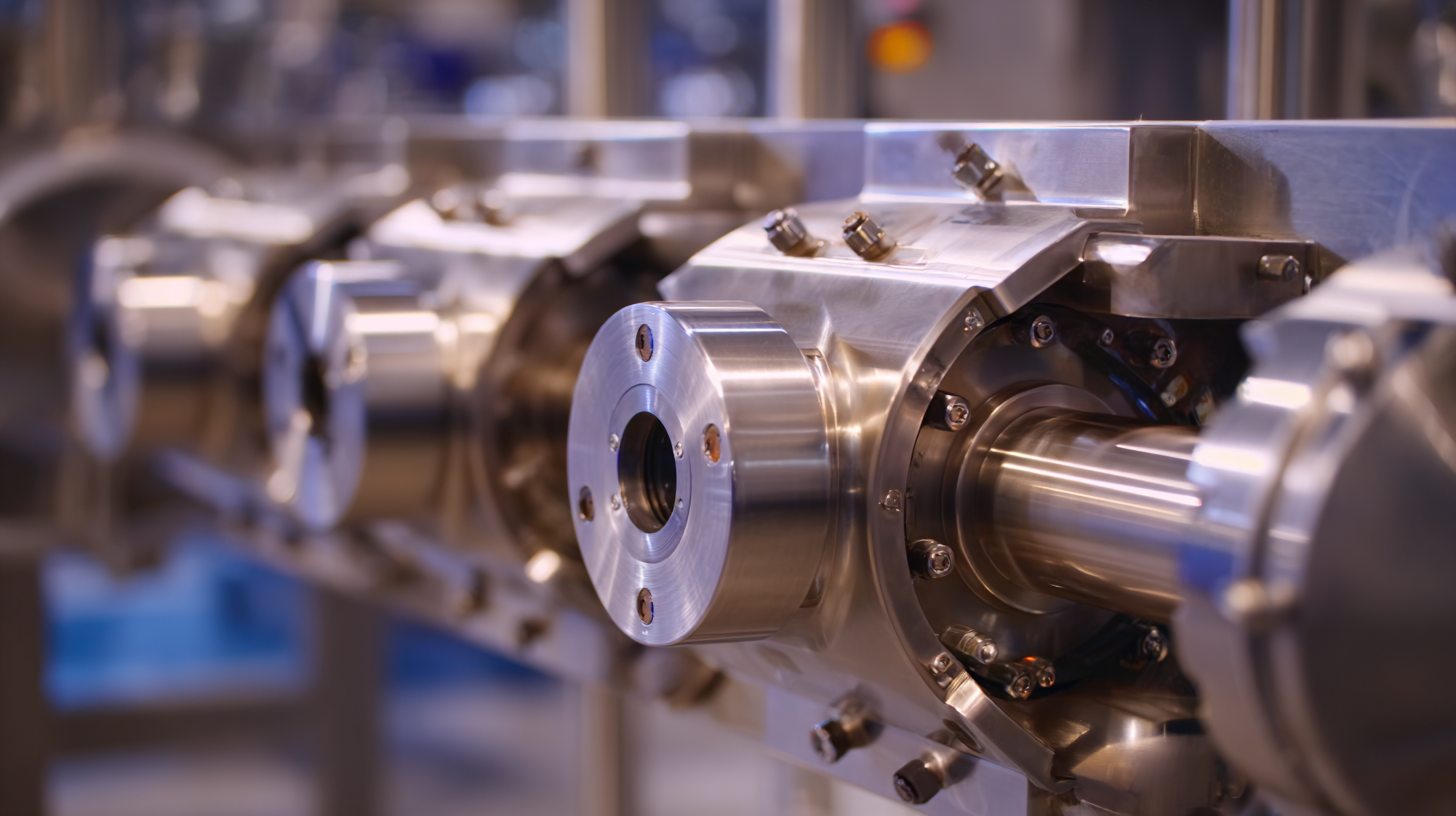

Extruder technology plays a pivotal role in revolutionizing food processing, enhancing product quality, and ensuring efficiency. High-performance extruders are designed with key technical parameters that optimize processes such as temperature control, pressure management, and feed rate accuracy. These parameters directly impact the texture and flavor of the final product, making it essential for manufacturers to select extruders that meet specific processing needs.

Tip: When selecting an extruder, consider its capability to maintain consistent temperature profiles throughout production. This is crucial for applications like puffed snacks and pasta, where precise cooking temperatures influence the finished product's quality.

Another vital parameter is the screw design, which affects material flow and mixing efficiency. A properly designed screw can enhance the shear forces exerted on ingredients, leading to better hydration and dough formation. It's essential to assess the extruder's design based on the intended application, as different products require varied shear rates and mixing patterns.

Tip: Regularly monitor and fine-tune extruder parameters to achieve optimal performance. Small adjustments can lead to significant improvements in product quality and energy efficiency, ultimately contributing to a more sustainable production process.

Innovative Applications of Extruder Technology in the Food Industry

The food industry is witnessing a transformative shift thanks to advanced extruder technology, which is paving the way for innovative applications that enhance food processing. Extruders play a crucial role in the production of a variety of food products, including snacks, cereals, and meat substitutes. By applying heat and pressure, extruders enable the mixing and cooking of raw ingredients, producing highly nutritious and palatable items with improved texture and shelf life. This technology not only boosts efficiency but also significantly reduces waste, catering to the growing demand for sustainable food solutions.

At Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., we have over 25 years of experience in creating state-of-the-art feed processing machinery, including pellet mill dies tailored for efficient food production. Our commitment to innovation ensures that we provide the best extruder solutions for food processing applications, empowering businesses to optimize their production methods while adhering to environmental protection standards. By integrating superior extruder technology, we facilitate the development of high-quality food products that meet the needs of today’s consumers, all while promoting sustainable practices in the industry.

Step-by-Step Guide to Selecting the Right Extruder for Your Needs

When selecting the right extruder for food processing, it’s imperative to understand the various types available and their specific applications. According to a 2022 report by Grand View Research, the global food extruder market was valued at approximately $2.2 billion and is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. This growth underscores the increasing demand for customized food products, which require precise extrusion technologies.

The first step in choosing an extruder involves determining the type of food product you wish to create. Twin-screw extruders, for instance, are preferred for their versatility and efficiency in handling a wide range of formulations, as noted in a recent industry analysis published by MarketsandMarkets. For products requiring specific textural qualities, single-screw extruders may be more suitable due to their lower shear capabilities. Moreover, considering the extruder's capacity, energy efficiency, and maintenance requirements is vital in ensuring optimal production costs and minimizing downtime. By evaluating these factors, manufacturers can select an extruder that not only meets their current needs but also adapts to future innovations in food processing technology.

Revolutionizing Food Processing with the Best Extruder Technology and Applications

| Extruder Type | Applications | Production Capacity (kg/h) | Energy Consumption (kWh/kg) | Main Advantages |

|---|---|---|---|---|

| Single-Screw Extruder | Snacks, Pet Foods | 100-300 | 1.2 | Simple design, lower cost |

| Twin-Screw Extruder | Pasta, Textured Protein | 200-600 | 1.5 | High mixing efficiency, better control |

| Screen-less Extruder | Snacks, Cereals | 150-450 | 1.0 | Reduced wear, better for high-fiber |

| Co-Rotating Extruder | Food, Pharmaceuticals | 300-700 | 1.4 | Versatile applications, high throughput |

Future Trends in Extrusion Technology and Food Processing

As the food processing industry continues to evolve, extrusion technology is at the forefront of this transformation. By 2024, the global food processing systems market is projected to reach USD 60.63 billion, with expectations to surge to USD 96.68 billion by 2033. This rapid growth underscores a significant shift towards innovative food processing methods that utilize advanced extruder technology. Extrusion not only enhances the efficiency of food production but also improves product quality, making it essential in addressing the evolving needs of consumers today.

In the face of increasing consumer demands for sustainable and innovative food products, the current trends in extrusion technology are driving the industry forward. From plant-based alternatives to functional snacks, advancements in extruder design and functionality are enabling food manufacturers to create diverse offerings that cater to health-conscious consumers. Moreover, the rise of artificial intelligence is poised to further revolutionize food processing, allowing for more efficient production lines and optimized recipes. With food technology becoming integral to meeting modern consumer expectations, investing in extrusion technologies promises substantial opportunities for growth and innovation in the food sector.

Case Studies: Successful Implementations of Extruder Technology

In recent years, the use of extruder technology in food processing has proven transformative, with numerous case studies showcasing its successful applications across various sectors. For instance, a leading snack food company adopted a state-of-the-art twin-screw extruder to enhance its production of puffed snacks. The results were remarkable: not only did they achieve a 30% increase in output, but the product's texture and flavor profile significantly improved, garnering positive feedback from consumers. This implementation highlighted the extruder's capability to create uniform products with enhanced nutritional content, all while maintaining a streamlined manufacturing process. Another compelling case involves a plant-based protein manufacturer that utilized extruder technology to develop meat alternatives. By leveraging the precise control of temperature and pressure offered by extruders, the company was able to texturize soy protein, mimicking the fibrous structure of traditional meat. This innovation not only appealed to a growing demographic of health-conscious and environmentally aware consumers but also positioned the company as a leader in the rapidly expanding plant-based market. These examples illustrate how adopting advanced extruder technology can streamline operations and elevate product quality, driving success in the competitive food processing landscape.

Another compelling case involves a plant-based protein manufacturer that utilized extruder technology to develop meat alternatives. By leveraging the precise control of temperature and pressure offered by extruders, the company was able to texturize soy protein, mimicking the fibrous structure of traditional meat. This innovation not only appealed to a growing demographic of health-conscious and environmentally aware consumers but also positioned the company as a leader in the rapidly expanding plant-based market. These examples illustrate how adopting advanced extruder technology can streamline operations and elevate product quality, driving success in the competitive food processing landscape.

FAQS

: Extruder technology plays a crucial role in enhancing product quality and efficiency in food processing by optimizing key parameters like temperature control, pressure management, and feed rate accuracy.

Consistent temperature control is essential for applications such as puffed snacks and pasta, as precise cooking temperatures significantly influence the quality of the finished product.

The screw design impacts material flow and mixing efficiency. A well-designed screw enhances shear forces on ingredients, leading to improved hydration and dough formation.

Manufacturers should assess the extruder's design based on the intended application, as different products require specific shear rates and mixing patterns.

Regularly fine-tuning extruder parameters can lead to significant improvements in product quality and energy efficiency, contributing to a more sustainable production process.

The global food processing systems market is projected to reach USD 60.63 billion by 2024 and surge to USD 96.68 billion by 2033.

Increasing consumer demands for sustainable and innovative food products are driving advancements in extrusion technology, including the development of plant-based alternatives and functional snacks.

The rise of artificial intelligence is anticipated to revolutionize food processing by enabling more efficient production lines and optimized recipes.

Investing in extrusion technologies promises substantial opportunities for growth and innovation in the food sector, addressing modern consumer expectations.

Extrusion technology is integral to creating diverse food offerings that cater to health-conscious consumers, reflecting the industry's shift towards innovation in food processing methods.

Related Posts

-

7 Compelling Reasons Your Next Investment Should Be the Best Feed Mill Plant

-

Innovative Solutions for Achieving the Best Die Design in Manufacturing

-

Global Buyers Choose Powerhouse Factories for Superior Feed Machines Made in China

-

Uncompromising Quality in Global Biomass Pelleting Manufacturing from China

-

7 Key Features That Make the Best Pellet Making Machines Drive 30% Higher Production Efficiency

-

Solutions for Optimal Efficiency in Best Animal Feed Processing Machine Production

Blog Tags: