Understanding the Innovative Solutions of Mould Tech Industries: A Comprehensive Guide

Table of Contents

- Exploring the Range of Alternative Solutions Offered by Mould Tech Industries

- Key Innovations in Mould Technology: A Look at Alternative Materials

- Sustainability in Mould Tech: Eco-Friendly Alternatives to Traditional Methods

- Challenges in Implementing Alternative Solutions in Mould Industries

- Future Trends: The Evolving Landscape of Alternatives in Mould Technology

- Case Studies: Successful Applications of Alternative Solutions by Mould Tech Industries

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of feed processing and aquaculture, innovative solutions provided by companies like Mould Tech Industries play a crucial role in enhancing operational efficiency and sustainability. With over 25 years of experience, Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY) specializes in manufacturing feed processing machineries and producing pellet mill dies, catering to the growing demand for high-quality feed solutions. According to industry reports, the global feed machinery market is projected to reach USD 23.7 billion by 2029, driven by rising livestock production and the need for environmentally sustainable practices. This comprehensive guide will delve into the innovative approaches of Mould Tech Industries, highlighting the significant impact of advanced technologies on improving production capabilities and promoting environmental protection in feed plants and aquaculture farms.

Exploring the Range of Alternative Solutions Offered by Mould Tech Industries

Mould Tech Industries stands at the forefront of innovation, offering a diverse array of alternative solutions tailored to meet the ever-evolving needs of various industries. Among its key offerings are advanced moulding techniques that encompass both traditional and modern materials. By integrating cutting-edge technology with sustainable practices, Mould Tech is able to deliver products that not only enhance efficiency but also minimize environmental impact. This commitment to innovation sets the company apart as a leader in moulding solutions.

One of the standout features of Mould Tech Industries is its dedication to customization. Understanding that every project is unique, the company collaborates closely with clients to develop bespoke solutions that align with specific requirements and challenges. From prototype development to large-scale production, their extensive range of services ensures that customers receive the best possible outcome. With a focus on flexibility and responsiveness, Mould Tech is well-equipped to adapt to changing industry trends and customer needs, solidifying its reputation as a reliable partner in the moulding industry.

Key Innovations in Mould Technology: A Look at Alternative Materials

In recent years, the moulding industry has seen a significant shift towards innovative solutions that prioritize sustainability and efficiency. One of the most notable trends is the exploration of alternative materials that reduce reliance on traditional plastics. Biodegradable composites, for instance, are gaining traction for their ability to decompose naturally, minimizing environmental impact while maintaining functionality. These materials not only meet regulatory demands but also appeal to eco-conscious consumers looking for greener product options.

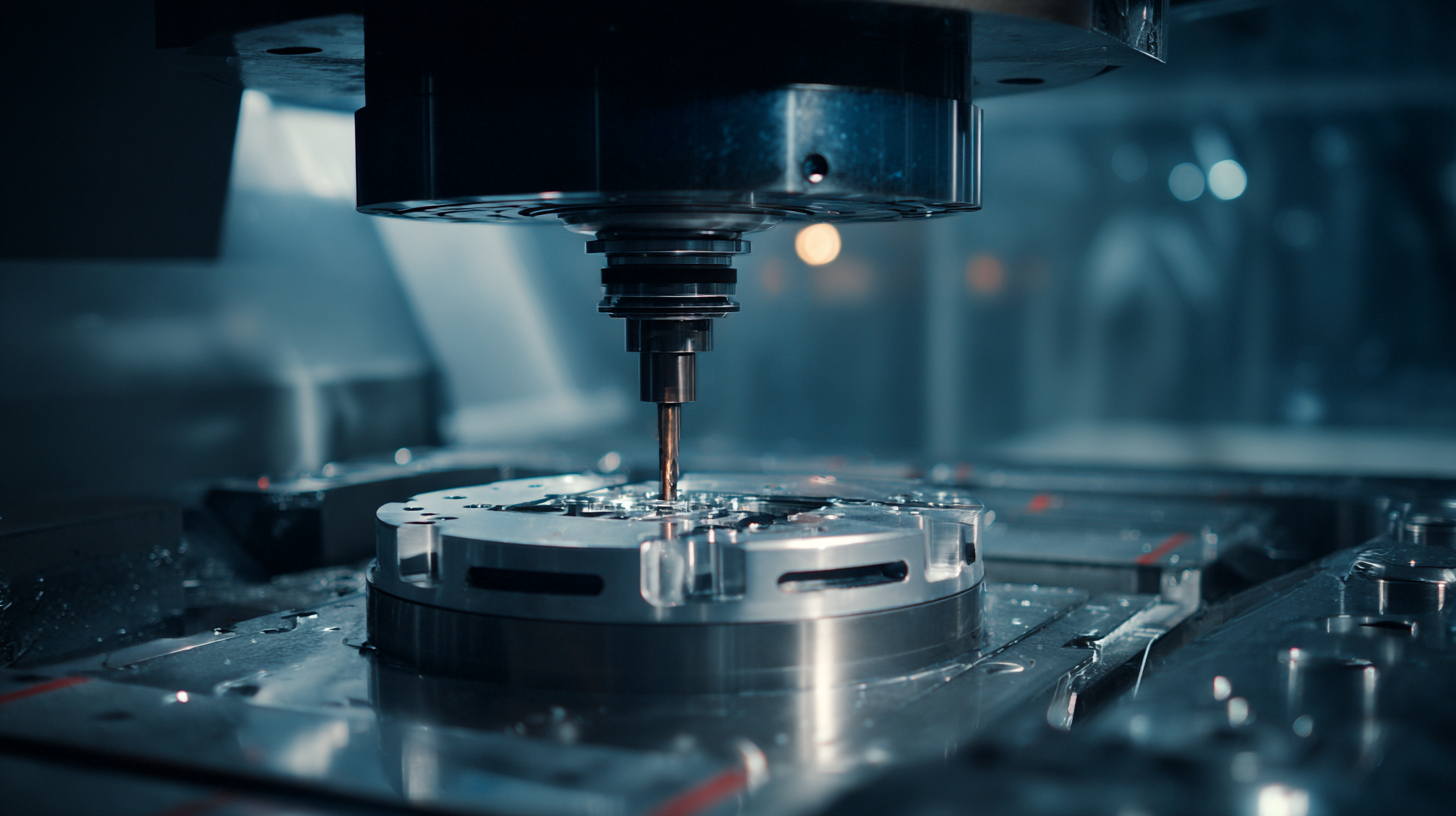

Another exciting development in mould technology is the use of advanced manufacturing techniques, such as 3D printing and additive manufacturing. These methods allow for unparalleled design flexibility and the ability to create complex geometries that would be impossible with conventional moulding processes. By leveraging these technologies, companies can utilize alternative materials more effectively, producing lightweight yet durable components that cater to a wide range of applications. This interplay between innovative materials and cutting-edge manufacturing techniques is shaping a new era in mould tech that embraces both performance and environmental stewardship.

Sustainability in Mould Tech: Eco-Friendly Alternatives to Traditional Methods

In recent years, Mould Tech Industries has made significant strides towards sustainability, emphasizing eco-friendly alternatives to traditional moulding processes. According to a report by the British Plastics Federation, the moulding industry significantly contributes to global plastic waste, with nearly 300 million tons produced annually. In response, Mould Tech has introduced innovative techniques that not only reduce waste but also lower emissions. Their adoption of biodegradable materials and recycling technologies is demonstrating a viable path forward, where the environmental impact is minimized.

Additionally, Mould Tech's commitment to sustainability aligns with the global trend towards circular economy practices. A recent study published in the Journal of Cleaner Production highlighted that implementing sustainable manufacturing practices can reduce energy consumption by up to 50% and decrease CO2 emissions by 30%. By integrating renewable energy sources in their production lines and utilizing advanced machinery designed for efficiency, Mould Tech not only enhances its operational performance but also sets a benchmark in the moulding industry for responsible manufacturing practices, showcasing that eco-friendly alternatives can be both effective and profitable.

Understanding the Innovative Solutions of Mould Tech Industries: A Comprehensive Guide - Sustainability in Mould Tech: Eco-Friendly Alternatives to Traditional Methods

| Aspect | Description | Eco-Friendly Method | Benefits |

|---|---|---|---|

| Raw Materials | Sourcing sustainable and biodegradable materials for production. | Use of recycled plastics and natural composites | Reduces waste and lowers carbon footprint. |

| Manufacturing Process | Implementing energy-efficient machinery and techniques. | Adoption of 3D printing technologies | Minimizes material waste and energy consumption. |

| Packaging | Using minimal and recyclable packaging methods. | Biodegradable packaging solutions | Decreases landfill contributions and waste disposal issues. |

| Supply Chain Management | Optimizing logistics for reduced emissions. | Local sourcing and transportation efficiency | Lower environmental impact and supports local economies. |

| Waste Management | Implementing circular economy principles. | Recycling and upcycling waste materials | Promotes sustainability and reduces resource dependency. |

Challenges in Implementing Alternative Solutions in Mould Industries

The mould industry is facing a dynamic shift towards innovative solutions, yet implementing alternative technologies presents significant challenges. One major hurdle is the initial investment required for new equipment and processes. Many companies are hesitant to allocate substantial funds without a guaranteed return on investment. This reluctance can slow down the adoption of necessary advancements that could boost efficiency and sustainability within the industry.

Another significant challenge is the need for workforce training and adaptation. As new technologies emerge, existing employees must acquire new skills and learn to operate sophisticated machinery. This transition not only requires time and resources but also poses a risk of temporary productivity loss during the training phase. Companies must strike a balance between integrating new solutions and maintaining their current operations, creating a complex scenario for management teams.

Moreover, the mould industry often faces regulatory and compliance obstacles when introducing alternative solutions. Different regions may have varying standards regarding materials and manufacturing processes, making it difficult to implement a one-size-fits-all solution. Companies must navigate these regulations carefully, ensuring that their innovative approaches align with legal requirements while striving for environmental advancements.

Future Trends: The Evolving Landscape of Alternatives in Mould Technology

As the mould technology sector evolves, the demand for innovative alternatives is driving significant change. Companies are increasingly looking to sustainable materials and advanced techniques to enhance their manufacturing processes. With a growing emphasis on reducing environmental impact, initiatives such as the use of bio-based polymers are becoming mainstream. These materials not only offer better performance but also align with the rising consumer preference for eco-friendly products.

Tip: When considering alternatives in mould technology, evaluate the life cycle of the materials you choose. Assessing their sourcing, usability, and end-of-life recyclability can provide insights into their sustainability impact.

Additionally, digital technologies such as 3D printing are transforming mould creation. This approach allows for rapid prototyping, reducing both time and costs compared to traditional methods. It also fosters greater flexibility in design, enabling manufacturers to respond quickly to market trends and customize products efficiently.

Tip: Embrace emerging technologies by investing in training for your team. Understanding how to leverage these innovations can significantly enhance productivity and keep you ahead in the competitive landscape of mould technology.

Future Trends in Mould Technology

Case Studies: Successful Applications of Alternative Solutions by Mould Tech Industries

Mould Tech Industries has been at the forefront of innovation, addressing complex challenges in manufacturing through alternative solutions. Their recent case studies provide compelling insights into how these innovative approaches have been effectively implemented across various sectors. For instance, the integration of 3D printing technology has resulted in a 30% reduction in production time and a 25% decrease in material waste, as highlighted in a 2022 industry report by the Global Manufacturing Alliance.

In the automotive sector, Mould Tech Industries successfully applied their expertise in thermoplastics, leading to lightweight components that enhanced fuel efficiency by up to 15%. This outcome not only meets environmental regulations but also aligns with consumer demand for sustainable vehicles. Furthermore, a case study published by the Auto Industries Journal noted that companies leveraging Mould Tech's solutions saw an average increase of 20% in operational efficiency. These examples underline the critical role that innovative problem-solving plays in evolving manufacturing landscapes, showcasing Mould Tech Industries as a leader in implementing best practices and delivering tangible results.

FAQS

: Mould Tech Industries has introduced eco-friendly alternatives to traditional moulding processes, focusing on reducing waste and lowering emissions through biodegradable materials and recycling technologies.

Implementing sustainable manufacturing practices can reduce energy consumption by up to 50% and decrease CO2 emissions by 30%, according to a study from the Journal of Cleaner Production.

Bio-based polymers are increasingly being used in the mould technology sector as they offer better performance and align with consumer preferences for eco-friendly products.

3D printing allows for rapid prototyping, reduces production time and costs, and provides greater flexibility in design, enabling manufacturers to quickly respond to market trends.

Advanced machinery can enhance operational performance while integrating renewable energy sources, setting a benchmark for responsible manufacturing practices in the moulding industry.

Mould Tech's use of 3D printing technology resulted in a 30% reduction in production time and a 25% decrease in material waste.

Mould Tech's expertise in thermoplastics led to the creation of lightweight components that enhanced fuel efficiency by up to 15%, meeting environmental regulations and consumer demand for sustainable vehicles.

Evaluating the life cycle of materials helps assess their sourcing, usability, and end-of-life recyclability, providing insights into their overall sustainability impact.

Companies should invest in training for their teams to understand and leverage emerging digital technologies, which can enhance productivity and maintain competitive advantage in the mould technology sector.

Companies using Mould Tech's innovative approaches reported an average increase of 20% in operational efficiency, highlighting the effectiveness of their sustainable manufacturing practices.

Conclusion

In the blog titled "Understanding the Innovative Solutions of Mould Tech Industries: A Comprehensive Guide," we delve into the diverse range of alternative solutions offered by Mould Tech Industries. The discussion highlights key innovations in mould technology, particularly focusing on alternative materials that not only enhance product performance but also promote sustainability. By presenting eco-friendly alternatives to traditional methods, Mould Tech Industries positions itself at the forefront of environmental protection initiatives within the manufacturing sector.

Additionally, the blog addresses the challenges faced in implementing these innovative solutions and speculates on future trends within the mould technology landscape. Through case studies demonstrating successful applications, Mould Tech Industries exemplifies how embracing alternative solutions can lead to significant advancements and contribute to a more sustainable and efficient industry. In alignment with these innovations, companies like Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. are also making strides in eco-friendly practices, particularly in the realm of feed processing machinery and environmental solutions.

Related Posts

-

How to Navigate Import and Export Certifications for Best Mould Tech Industries

-

Innovative Solutions for Achieving the Best Die Design in Manufacturing

-

Challenges in Livestock Feed Pellet Mill Production: Navigating Quality and Efficiency Issues

-

Unlocking Efficiency in Livestock Management with the Ultimate Feed Mixer Machine

-

Mastering the Best Die Cutting Techniques with In-Depth Technical Specifications and Step by Step Guide

-

Exploring Unique Product Attributes for the Best Feed Mill Process and How to Choose the Right One

Blog Tags: