The Future of Ring Die Replacement Innovations Transforming Production Efficiency

Table of Contents

- Innovative Materials for Enhanced Ring Die Durability

- Advancements in Ring Die Design for Optimal Performance

- Technological Integration in Ring Die Replacement Processes

- Environmental Impacts of Modern Ring Die Manufacturing

- Case Studies: Success Stories in Production Efficiency with New Innovations

- FAQS

- Related Posts

The feed processing industry is on the cusp of a significant transformation, driven by innovations in Ring Die Replacement technology. According to recent industry reports, the global feed machinery market is projected to reach $30 billion by 2025, with a CAGR of over 4% as demand for efficient and sustainable production methods rises. Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY) has been at the forefront of this evolution, leveraging over 25 years of expertise in manufacturing feed processing machinery and pellet mill dies. As environmental concerns become increasingly critical, our commitment to providing advanced solutions for feed plants and aquaculture farms underscores the importance of Ring Die Replacement in enhancing production efficiency while minimizing ecological impact. This blog will explore the future of Ring Die Replacement innovations and their role in reshaping production strategies in the feed industry.

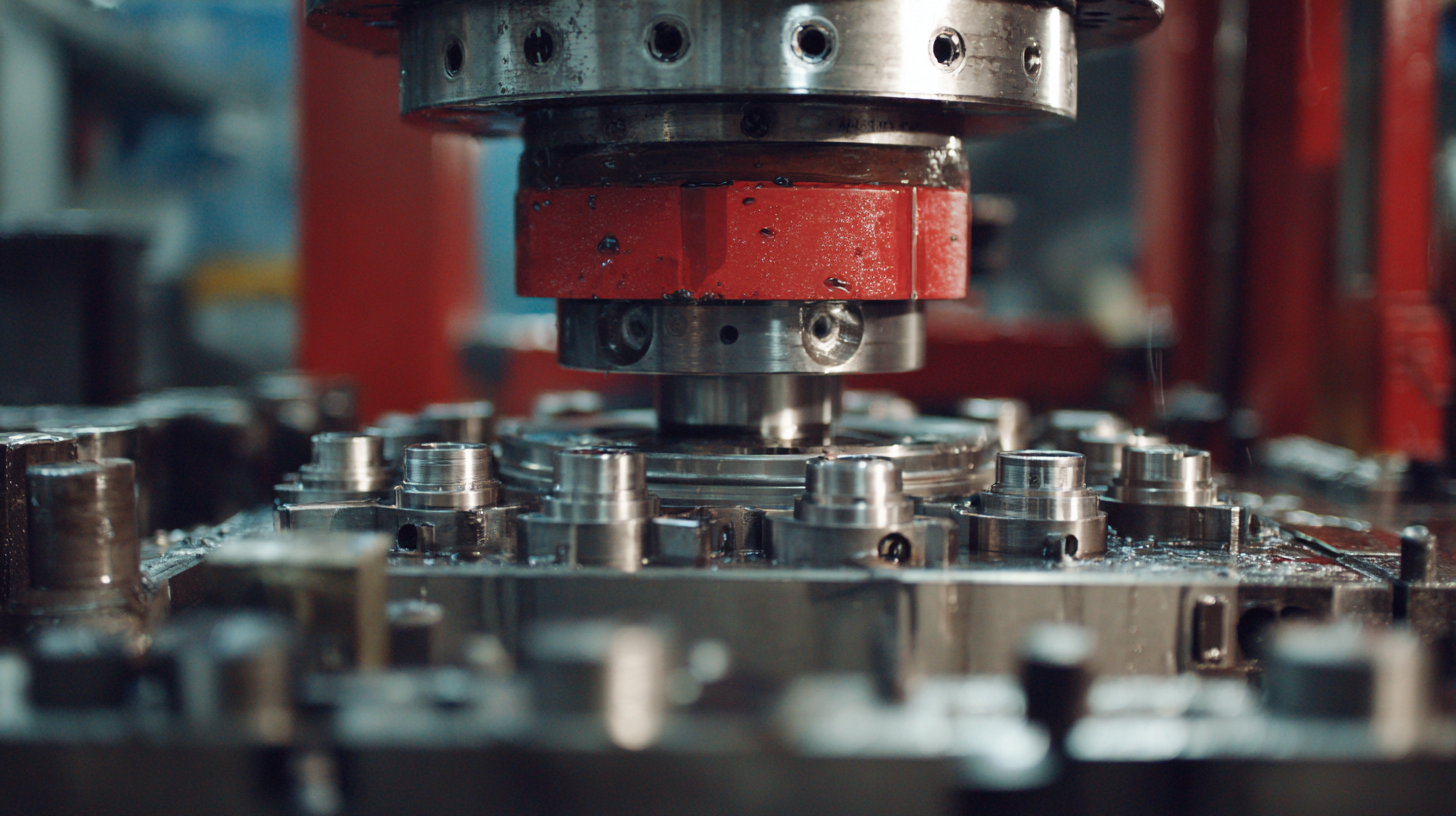

Innovative Materials for Enhanced Ring Die Durability

Innovative materials are ushering in a new era of ring die durability, essential for enhancing production efficiency in industries like animal feed and biomass processing. Recent industry reports indicate that the adoption of advanced alloys and composites in ring die production can extend their lifespan by up to 30%. These materials not only improve wear resistance but also maintain structural integrity under high-stress conditions, thus reducing the frequency of replacements and downtime. As manufacturers strive for greater efficiency, the materials selected for ring dies are critical in determining overall performance.

Innovative materials are ushering in a new era of ring die durability, essential for enhancing production efficiency in industries like animal feed and biomass processing. Recent industry reports indicate that the adoption of advanced alloys and composites in ring die production can extend their lifespan by up to 30%. These materials not only improve wear resistance but also maintain structural integrity under high-stress conditions, thus reducing the frequency of replacements and downtime. As manufacturers strive for greater efficiency, the materials selected for ring dies are critical in determining overall performance.

Consider implementing regular maintenance schedules to maximize the lifespan of your ring dies. Keeping the dies clean and monitoring their condition can prevent unexpected failures. Using innovative coatings can further protect ring dies from abrasive wear and corrosion, significantly enhancing their durability. Furthermore, investing in high-quality, engineered materials may result in better pellet quality and lower energy consumption, contributing to long-term cost savings and improved environmental performance.

As innovations continue to shape the industry, adopting the latest advancements in material science will be crucial for companies looking to maintain a competitive edge. Tailoring your choice of ring die materials to specific production needs can lead to significant improvements in both output and quality.

Advancements in Ring Die Design for Optimal Performance

In the dynamic landscape of feed production, advancements in ring die design are paving the way for improved efficiency and performance. At Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY), our expertise in manufacturing feed processing machinery for over 25 years positions us at the forefront of these innovations. Modern ring dies are engineered to optimize the pelleting process, ensuring consistent feed quality and reducing energy consumption. The integration of advanced materials and precision engineering techniques allows for greater durability and longer operational lifespans, which is essential for large-scale production.

Moreover, the continual evolution of ring die technology not only enhances the efficiency of feed production but also aligns with sustainability practices. Our commitment to providing environmental protection systems and solutions for feed plants and aquaculture farms showcases our dedication to combining innovation with ecological responsibility. By adopting these cutting-edge designs, feed producers can achieve higher productivity while minimizing their environmental impact, ultimately driving the industry towards a more sustainable future.

The Future of Ring Die Replacement Innovations Transforming Production Efficiency

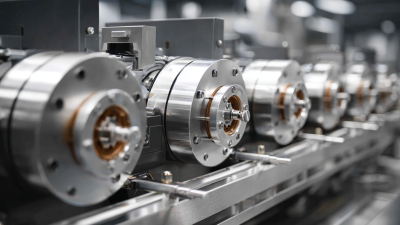

Technological Integration in Ring Die Replacement Processes

The integration of advanced technologies into ring die replacement processes is revolutionizing production efficiency in various industries. With the market for pellet dies projected to reach $1.1 billion by 2026, driven by innovations in manufacturing techniques, companies are increasingly adopting automated solutions that streamline the replacement process. According to a recent report by MarketsandMarkets, the implementation of IoT and AI in die replacement systems can potentially reduce downtime by up to 30%, allowing for smoother operations and increased output.

Moreover, the rising trend of predictive maintenance powered by machine learning algorithms is taking production efficiency to new heights. By continuously monitoring wear and tear on ring dies, manufacturers can forecast potential failures, thereby scheduling timely replacements that minimize disruption. A study from Deloitte indicates that such predictive analytics can enhance equipment lifespan by 20%, translating into significant savings on both maintenance costs and production losses. As technological integration continues to evolve, the role of ring die replacement will be pivotal in shaping the future landscape of production efficiency.

Environmental Impacts of Modern Ring Die Manufacturing

The manufacturing of ring dies, essential components in pellet production, significantly influences environmental sustainability within the industry. Recent reports indicate that traditional ring die manufacturing methods yield substantial waste, with estimates suggesting that up to 40% of raw materials can be lost during the production process. This not only affects resource efficiency but also contributes to higher carbon emissions associated with the waste disposal and the energy consumed during manufacturing.

Innovative technologies and materials are emerging to mitigate these environmental impacts. For instance, advancements in precision engineering have improved the accuracy of die cuts, reducing material wastage to as little as 10%. Moreover, the introduction of recycled materials in die fabrication processes has gained traction, with studies showing that utilizing recycled metals can lower the carbon footprint by approximately 25%. As the industry shifts towards greener practices, the integration of sustainable raw materials and enhanced production efficiencies highlights a critical step in reducing the ecological footprint of ring die manufacturing.

The Future of Ring Die Replacement Innovations Transforming Production Efficiency - Environmental Impacts of Modern Ring Die Manufacturing

| Dimension | Measurement | Impact | Innovation Examples |

|---|---|---|---|

| Production Efficiency | 30% Increase | Lower operational costs | Advanced manufacturing techniques |

| Material Sustainability | 50% Recycled Materials | Reduced environmental footprint | Bio-based composites |

| Lifecycle Duration | 5 Years | Less frequent replacements | Tool optimization strategies |

| Energy Consumption | 20% Reduction | Lower carbon emissions | Energy-efficient manufacturing processes |

| Waste Generation | 15% Decrease | Minimized landfill contributions | Closed-loop manufacturing |

Case Studies: Success Stories in Production Efficiency with New Innovations

The future of ring die replacement innovations is transforming production efficiency across various industries. Notable case studies highlight organizations that have adopted advanced ring die technologies, showcasing remarkable improvements in their operational workflows. For instance, a leading animal feed manufacturer recently implemented a new modular ring die system, reducing changeover times by 40%. This allowed them to respond quickly to shifts in customer demand while maintaining high product quality.

Tips for businesses looking to innovate their production processes include investing in training for staff on new technologies to ensure optimal use of equipment. Additionally, regularly analyzing performance data can provide insights into further improvements and help identify areas where efficiency can be enhanced. Another key strategy is to collaborate with suppliers for the latest advancements, enabling the integration of cutting-edge techniques into daily operations.

By examining these success stories, companies can understand the significant effects of innovative ring die replacements on their production lines, often leading to reduced costs and increased output. Adopting these innovations not only enhances efficiency but also positions businesses favorably in a competitive market.

FAQS

: Innovative materials, such as advanced alloys and composites, can extend the lifespan of ring dies by up to 30%, improve wear resistance, and maintain structural integrity under high-stress conditions, reducing replacements and downtime.

Implementing regular maintenance schedules, keeping dies clean, and monitoring their condition can prevent unexpected failures and maximize the lifespan of ring dies.

Innovative coatings can protect ring dies from abrasive wear and corrosion, significantly enhancing their overall durability.

The integration of IoT and AI in die replacement systems can reduce downtime by up to 30%, streamlining operations and increasing output.

Predictive maintenance uses machine learning algorithms to continuously monitor wear and tear on ring dies, allowing manufacturers to forecast potential failures and schedule timely replacements to minimize disruption.

Traditional methods can result in up to 40% raw material waste, which affects resource efficiency and contributes to higher carbon emissions from waste disposal and energy consumption.

Precision engineering has improved die cut accuracy, reducing material wastage to as little as 10%, and the introduction of recycled materials in die fabrication processes can lower the carbon footprint by approximately 25%.

Adopting the latest advancements in material science can help companies maintain a competitive edge, improve production efficiency, and enhance both output and product quality.

Investing in high-quality, engineered materials can lead to better pellet quality and lower energy consumption, resulting in long-term cost savings and improved environmental performance.

The market for pellet dies is projected to reach $1.1 billion by 2026, driven by innovations in manufacturing techniques and the adoption of automated solutions.

Related Posts

-

Global Buyers Choose Powerhouse Factories for Superior Feed Machines Made in China

-

Revolutionizing Global Feed Production: China's Best Poultry Mash Feed Machine Leading the Charge

-

7 Compelling Reasons Your Next Investment Should Be the Best Feed Mill Plant

-

Mastering the Best Die Cutting Techniques with In-Depth Technical Specifications and Step by Step Guide

-

Exploring Unique Product Attributes for the Best Feed Mill Process and How to Choose the Right One

-

Revolutionizing Food Processing with the Best Extruder Technology and Applications

Blog Tags: