Drum Mixer Shaft: A Comprehensive Comparison of Materials and Designs for Optimal Performance

Table of Contents

- Key Materials for Drum Mixer Shafts: Analyzing Strength and Durability

- Understanding Design Variations: How Shape Influences Mixing Efficiency

- The Role of Shaft Coatings: Enhancing Performance and Longevity

- Weight Considerations: Striking the Right Balance for Optimal Operation

- Cost vs. Performance: Evaluating Material Choices for Drum Mixers

- Maintenance Needs: How Material Selection Affects Longevity and Repairs

- FAQS

- Conclusion

- Related Posts

In the dynamic field of feed processing and aquaculture, the efficiency of production largely hinges on the quality of machinery components, particularly the Drum Mixer Shaft. According to a report by Grand View Research, the global feed processing market is projected to reach USD 733.64 billion by 2025, driving the need for high-performance mixing solutions. At Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY), we have been at the forefront of this revolution for over 25 years, specializing in the manufacturing of feed processing machinery and pellet mill dies. As the industry continues to evolve, understanding the various materials and designs of the Drum Mixer Shaft becomes crucial for achieving optimal performance and meeting environmental standards in feed plants and aquaculture farms. This blog will delve into the comparative analysis of different Drum Mixer Shaft materials and designs, highlighting the benefits and considerations for selecting the ideal solution for your operational needs.

Key Materials for Drum Mixer Shafts: Analyzing Strength and Durability

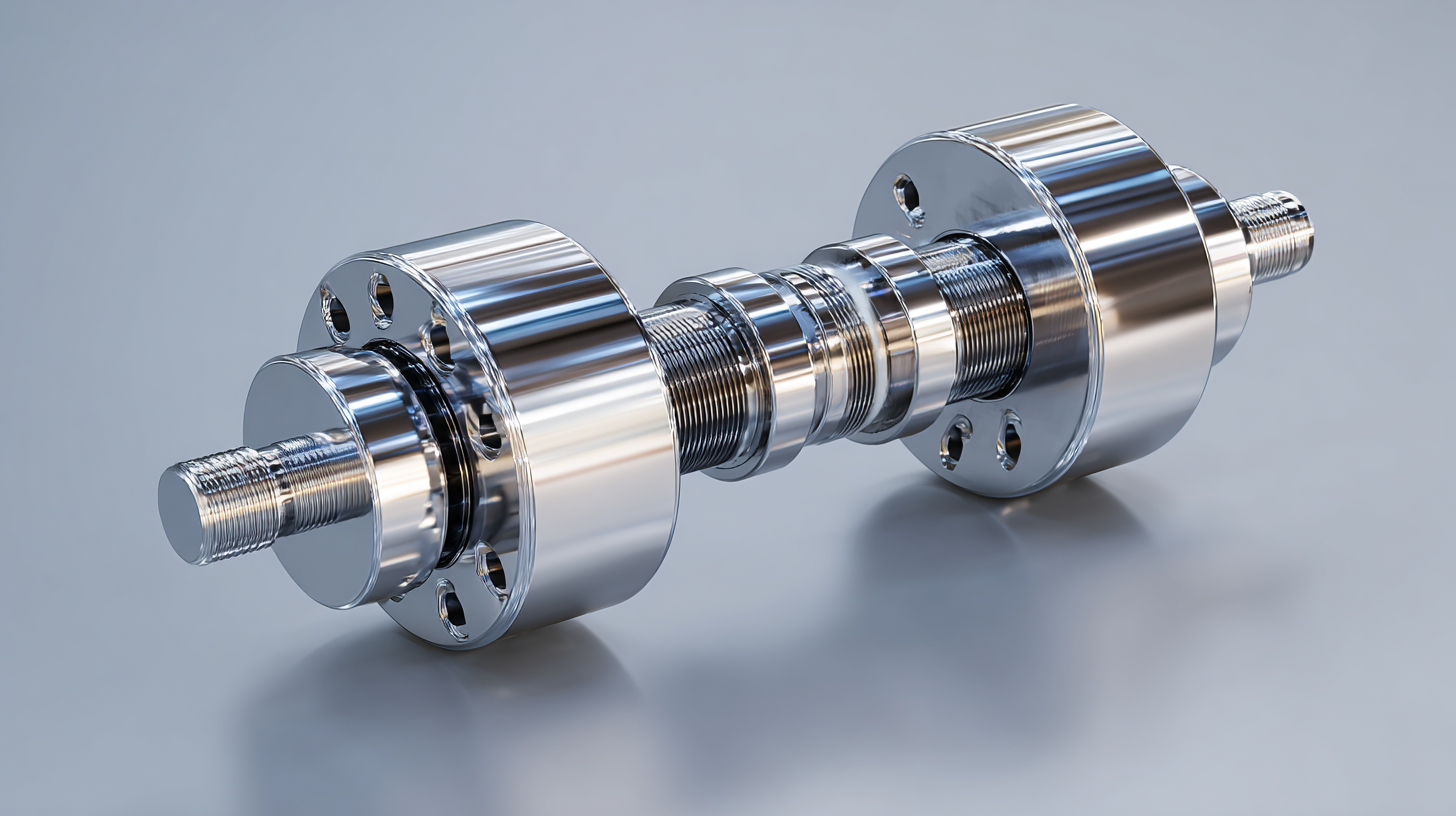

When selecting materials for drum mixer shafts, two key factors come to the forefront: strength and durability. The most common materials used in the production of these shafts include stainless steel, carbon steel, and various alloys.

Stainless steel is favored for its exceptional corrosion resistance and high tensile strength, making it ideal for environments requiring prolonged exposure to moisture and chemicals.

On the other hand, carbon steel, while less resistant to corrosion, provides high strength and is often used in applications where cost-effectiveness is a priority without sacrificing performance.

Alloy materials have been gaining popularity due to their ability to combine the desirable traits of different metals. For example, high-strength low-alloy (HSLA) steels offer the benefits of both durability and weight reduction, making them suitable for high-performance mixing applications. Additionally, newer composite materials have emerged, providing the potential for even lighter and stronger designs. The choice of material ultimately impacts the overall efficiency of the drum mixer, underscoring the importance of analyzing the specific demands of the mixing process when selecting the optimal shaft material for longevity and reliability.

Understanding Design Variations: How Shape Influences Mixing Efficiency

In the realm of drum mixers, the design of the mixing shaft plays a pivotal role in determining mixing efficiency. Recent studies indicate that variations in shaft shape can significantly impact the flow patterns within the drum, thereby influencing homogenization and consistency. For instance, a report by the Mixing Research Institute found that tapered and helical shaft designs promote better material flow and reduced dead zones, leading to a 20% increase in mixing efficiency compared to traditional cylindrical shafts.

Moreover, the width and length of the shaft are crucial factors that shape the mixing dynamics. A study published in the Journal of Industrial Mixing revealed that wider shafts facilitate a more aggressive mixing action, which is particularly beneficial in processes requiring fast blending of viscous materials. Conversely, narrower shafts can enhance precision in applications where uniformity is paramount.

Understanding these design variations not only aids in selecting the right mixer for a specific application but also emphasizes the importance of innovation in shaft design to enhance overall performance in various industries.

The Role of Shaft Coatings: Enhancing Performance and Longevity

When it comes to drum mixer shafts, the choice of materials and coatings can significantly influence their performance and longevity. The integration of advanced coatings not only enhances the mechanical properties of the shaft but also maximizes its resistance to wear and corrosion. For instance, utilizing MoS2-reinforced coatings can substantially improve the wear performance of stainless steels in tough environments, ensuring that the shafts maintain their integrity over prolonged usage.

Tips for enhancing performance through coatings include selecting the right material based on the specific application requirements. Coatings such as those based on advanced polymers can reduce friction and thus enhance overall efficiency. Additionally, regular maintenance checks should be conducted, especially in environments prone to corrosive elements, to ensure that the coating remains intact and functional.

Moreover, incorporating innovative coatings that adhere to the principles of sustainable practices can provide an edge in long-term operational efficiency. These coatings can be engineered to support not just performance but also align with emerging trends in eco-friendly manufacturing processes. Implementing such strategies can lead to notable improvements in the lifespan and reliability of drum mixer shafts, benefiting both production efficiency and sustainability.

Drum Mixer Shaft: A Comprehensive Comparison of Materials and Designs for Optimal Performance

| Material | Design | Coating Type | Performance Rating (1-10) | Longevity (Years) |

|---|---|---|---|---|

| Stainless Steel | Single Shaft | Polymer Coating | 9 | 8 |

| Carbon Steel | Double Shaft | Zinc Plating | 7 | 5 |

| Aluminum | Tapered Shaft | Anodized Coating | 8 | 6 |

| Titanium | Hollow Shaft | Ceramic Coating | 10 | 10 |

| Inconel | Straight Shaft | PTFE Coating | 9 | 12 |

Weight Considerations: Striking the Right Balance for Optimal Operation

When it comes to optimizing the performance of drum mixers, the choice of shaft materials and designs is critical, particularly in relation to weight considerations. A lighter shaft can enhance efficiency by reducing the energy required to operate the machinery. According to a report by the International Journal of Agronomy, the optimal weight of mixer shafts can impact operational efficiency by up to 15%, directly correlating to the reduction in material fatigue and maintenance costs.

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY) has been at the forefront of manufacturing feed processing machineries for over 25 years, focusing on the nuance of weight and material selection for drum mixer shafts. Utilizing advanced materials such as aluminum alloys and high-strength steels not only minimizes the weight but also maximizes durability. A study by the American Society of Agricultural and Biological Engineers indicates that selecting the right material can lead to a 20% increase in lifespan for mixer components, translating to lower operational downtime and enhanced productivity for feed plants and aquaculture farms.

In an industry where precision and longevity are key, manufacturers must balance weight and design features to achieve optimal operation. By leveraging over two decades of expertise, CPSHZY is committed to providing innovative solutions that meet the specific needs of our clients, ensuring that their equipment runs efficiently while adhering to environmental protection standards.

Cost vs. Performance: Evaluating Material Choices for Drum Mixers

When evaluating drum mixers, the choice of materials for the shaft is pivotal in balancing cost and performance. Different materials offer distinct advantages that can significantly impact the efficiency and longevity of the mixer. For instance, while stainless steel is often favored for its durability and resistance to corrosion, it tends to be more expensive. In contrast, carbon steel offers a budget-friendly alternative but may require additional coatings or treatments to enhance its resistance to wear and tear.

In addition to the material itself, the design of the mixer shaft plays a crucial role in overall performance. Innovative designs can help optimize mixing efficiency, reduce energy consumption, and minimize maintenance costs. For example, shafts designed with enhanced geometries promote better material flow and mixing uniformity. By carefully evaluating both material choices and design features, manufacturers can achieve a harmonious balance between performance and cost, ensuring that the drum mixer meets specific operational needs without exceeding budget constraints.

Maintenance Needs: How Material Selection Affects Longevity and Repairs

When it comes to drum mixer shafts, material selection plays a pivotal role not only in performance but also in maintenance needs over time. Different materials such as stainless steel, carbon steel, and aluminum each possess unique properties that affect their durability and resistance to wear and tear. For instance, stainless steel is known for its corrosion resistance, making it an ideal choice for environments where moisture and chemicals are prevalent. This characteristic significantly reduces the frequency of repairs, allowing for longer intervals between maintenance sessions.

On the other hand, carbon steel, while offering high strength and rigidity, may require more frequent maintenance due to its susceptibility to rust and corrosion if not properly coated. The choice of material directly influences the lifespan of the drum mixer shaft; higher quality materials might come with a steeper initial investment but can lead to lower total ownership costs because of minimized downtime and repair expenses. Understanding these implications not only aids in selecting the right shaft for specific mixing tasks but also in allocating resources effectively for maintenance, ensuring optimal performance throughout its service life.

Drum Mixer Shaft Material Comparison

FAQS

: The key materials used for drum mixer shafts include stainless steel, carbon steel, and various alloys.

Stainless steel is favored for its exceptional corrosion resistance and high tensile strength, making it ideal for environments with prolonged exposure to moisture and chemicals.

Carbon steel provides high strength and is often a cost-effective option, although it is less resistant to corrosion than stainless steel.

Alloy materials, such as high-strength low-alloy (HSLA) steels, combine desirable traits of different metals to offer durability and weight reduction suitable for high-performance applications.

Coatings enhance the mechanical properties of the shaft, improving wear resistance, reducing friction, and maximizing overall efficiency.

Material selection influences durability and resistance to wear; for example, stainless steel's corrosion resistance leads to fewer required maintenance sessions compared to carbon steel, which may rust if not properly coated.

Tips include selecting the right coating material for the application, conducting regular maintenance checks, and considering eco-friendly coatings to improve sustainability and operational efficiency.

Higher quality materials may involve a steeper initial investment but can lead to lower total ownership costs due to minimized downtime and repair expenses.

Analyzing specific demands helps ensure the optimal choice of shaft material for longevity and reliability, directly affecting the efficiency of the drum mixer.

Emerging trends include the use of sustainable coatings that support performance and align with eco-friendly manufacturing practices.

Conclusion

In the realm of feed processing, selecting the right Drum Mixer Shaft is crucial for optimizing performance and ensuring durability. Our blog delves into key materials, analyzing their strength and longevity, alongside understanding how design variations impact mixing efficiency. We discuss the significance of shaft coatings that enhance performance and extend the lifespan of the mixer, while also addressing weight considerations to achieve the ideal operational balance.

Furthermore, we evaluate the cost versus performance of various material choices for Drum Mixer Shafts, highlighting how these decisions can affect maintenance needs and overall longevity. With over 25 years of expertise, Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. is dedicated to providing advanced solutions for feed plants, ensuring that our products not only meet industry standards but also enhance efficiency in operations.

Related Posts

-

Advantages of Utilizing a Drum Mixer Shaft in Your Production Process

-

How to Choose the Best Forging Ring for Your Industrial Needs: A Comprehensive Guide

-

Essential Guide to Operating a Machine To Make Feed Pellets for Beginners

-

How to Optimize Your Poultry Feed Milling Machine for Maximum Efficiency and Output

-

Top Strategies for Enhancing Efficiency in Chicken Feed Milling Operations

-

Challenges Facing Global Buyers: Understanding Issues with Feed Pellet Manufacturing Machines

Blog Tags: