Understanding Die Steel Variants for Optimal Industrial Applications

Table of Contents

- Identify Key Properties of Die Steel for Industrial Use

- Explore Common Die Steel Types and Their Applications

- Evaluate Performance Characteristics of Different Die Steel Grades

- Assess Cost-Effectiveness of Various Die Steel Options

- Best Practices for Selecting Die Steel Based on Project Needs

- Maintenance Tips for Prolonging Die Steel Lifespan in Operations

- FAQS

- Conclusion

- Related Posts

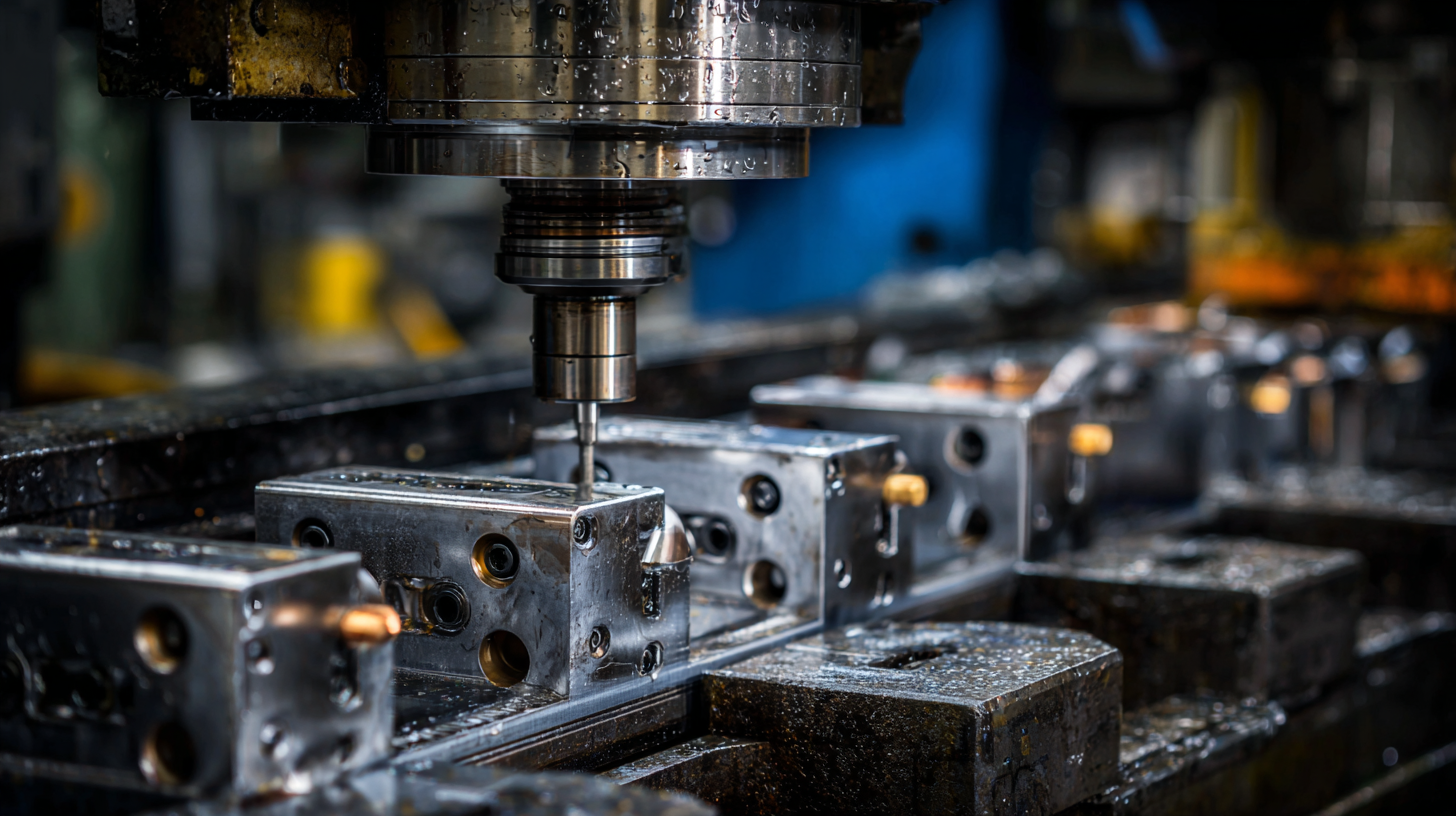

In the competitive landscape of industrial manufacturing, understanding the specific properties and applications of Die Steel variants is crucial for optimizing production processes. With over 25 years of experience, Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY) has been at the forefront of this sector, specializing in the production of feed processing machinery and pellet mill dies. According to recent industry reports, the global die steel market is projected to reach USD 10.6 billion by 2026, driven by the increasing demand for high-quality components in diverse sectors, including feed plants and aquaculture farms. Selecting the right Die Steel not only enhances product durability and performance but also significantly impacts operational efficiency. This blog will explore the various Die Steel variants available, their unique characteristics, and their tailored applications in industrial settings, providing valuable insights for maximizing productivity in your operations.

The importance of understanding Die Steel is evident in its varied properties and applications across different industries. These tailored applications not only meet specific production needs but also ensure that operational processes are efficient and effective.

Identify Key Properties of Die Steel for Industrial Use

When selecting die steel for industrial applications, understanding its key properties is crucial to ensure optimal performance. Die steels differ based on their chemical composition and heat treatment processes, which significantly influence their hardness, toughness, and wear resistance. High-speed steels, for instance, are renowned for their ability to retain hardness at elevated temperatures, making them suitable for cutting tools. Conversely, cold work tool steels offer superior toughness and resistance to cracking, ideal for forming applications.

Tips for selecting die steel include assessing the specific application requirements and operating conditions. For instance, if the die will undergo high thermal cycling, consider materials with excellent thermal fatigue resistance. Additionally, reviewing the die steel's machinability can save time during production. Some die steels, such as D2, provide good wear resistance but can be challenging to machine. Always balance the properties of hardness, toughness, and wear resistance to achieve the best results in your industrial applications.

Explore Common Die Steel Types and Their Applications

Die steel is an essential material in a broad range of industrial applications, and understanding its variants can significantly influence the efficiency and quality of the final products. Common die steel types include tungsten, chromium, and vanadium, each bringing unique properties to the table. For instance, according to the Asia Pacific Tool Steel Market Analysis, the demand for tungsten-based die steel is projected to grow, attributed to its superior hardness and heat resistance, making it ideal for applications in die work and injection molding.

The global tool steel market is anticipating significant growth, with projections suggesting a market worth of approximately $42.18 billion by 2029. This surge is driven by the increasing use of die steel variants across various sectors, including automotive and construction. In fact, the properties of die steel enhance the efficiency of industries relying on precision tools, which are crucial for high-volume production. The continuous development of advanced die steels is pivotal, not only to meet industry demands but also to streamline manufacturing processes effectively.

Understanding Die Steel Variants for Optimal Industrial Applications

| Die Steel Type | Composition | Hardness (HRC) | Applications | Benefits |

|---|---|---|---|---|

| D2 Tool Steel | Carbon, Chromium | 58-62 | Cold Work Dies, Stamping Tools | High wear resistance, good toughness |

| A2 Tool Steel | Carbon, Chromium | 55-60 | Blanking, Punching Tools | Good dimensional stability |

| O1 Tool Steel | Oil Hardening, Carbon | 55-62 | Cold Work, Dies | Easy to machine, good surface finish |

| M2 Tool Steel | Molybdenum, Tungsten | 62-66 | High-Speed Cutting Tools | High hardness, excellent cutting performance |

| H13 Tool Steel | Chromium, Molybdenum, Vanadium | 44-54 | Die Casting, Hot Work Applications | Good toughness, heat resistance |

Evaluate Performance Characteristics of Different Die Steel Grades

When evaluating the performance characteristics of different die steel grades, it is essential to consider the unique attributes that each variant brings to industrial applications. Recent advancements in materials science, such as high-performance plain carbon steels achieved through 3D printing, reveal that these steels can offer tensile and impact properties comparable to ultra-high strength alloys. This innovation suggests that traditional die steel grades may need to be reassessed against emerging alternatives that not only provide superior mechanical properties but also contribute to sustainability in manufacturing processes.

In particular, a comprehensive review of the laser powder bed fusion process for steels indicates that the ability to control microstructure and defects can significantly enhance the mechanical performance of die steels. The incorporation of advanced production technologies allows for targeted material characteristics that align directly with specific application requirements. Additionally, the unified stress-strain models developed for both normal and high strength steels provide valuable insights into predicting material behavior under various loads, making it crucial for engineers and designers to evaluate steel grades based on these enhanced performance parameters.

Assess Cost-Effectiveness of Various Die Steel Options

When selecting die steel for industrial applications, cost-effectiveness is a crucial consideration. According to a report by the International Trade Administration, the global market for tool and die steel is projected to reach $11 billion by 2025, with an annual growth rate of 5.3%. This growth underscores the importance of choosing the right steel variant that balances performance and affordability.

High-speed steel (HSS) and tool steel are among the most popular options, each with distinct advantages. HSS, for instance, typically costs around $6 to $8 per kilogram, but its ability to withstand high temperatures and maintain hardness makes it a long-lasting choice for many applications. In contrast, tool steel variants like D2 may range from $5 to $10 per kilogram but offer superior wear resistance, which can lead to lower replacement costs over time. Evaluating these options through a cost-benefit lens can significantly impact operational efficiency and profitability for manufacturers.

High-speed steel (HSS) and tool steel are among the most popular options, each with distinct advantages. HSS, for instance, typically costs around $6 to $8 per kilogram, but its ability to withstand high temperatures and maintain hardness makes it a long-lasting choice for many applications. In contrast, tool steel variants like D2 may range from $5 to $10 per kilogram but offer superior wear resistance, which can lead to lower replacement costs over time. Evaluating these options through a cost-benefit lens can significantly impact operational efficiency and profitability for manufacturers.

In addition to material costs, manufacturers should also factor in processing expenses. Data from the Society of Manufacturing Engineers shows that a 10% increase in tool durability can reduce operational costs by up to 30% due to fewer tool changes and less downtime. By carefully assessing these variables, businesses can make informed decisions that optimize both performance and cost-effectiveness in their die steel selections.

Best Practices for Selecting Die Steel Based on Project Needs

When selecting die steel for industrial applications, it is crucial to consider the specific requirements of the project. According to a report from the International Journal of Advanced Manufacturing Technology, up to 70% of production costs can be attributed to incorrect material selection. This emphasizes the need for a comprehensive understanding of die steel variants, which include options like cold work, hot work, and plastic mold steels, each possessing unique properties suitable for different applications.

For instance, cold work steels, such as D2 and O1, are known for their excellent wear resistance and hardness, making them ideal for high-precision tools. In contrast, hot work steels like H13 offer superior toughness and thermal resistance, suitable for dies used in forging and casting when high temperatures are prevalent. The choice of die steel can significantly influence not just the quality of the end product, but also the longevity of the tooling.

Industry experts recommend assessing factors such as production volume, cycle times, and the specific materials being processed to ensure the selected die steel aligns with project needs for optimal performance and cost-effectiveness.

Maintenance Tips for Prolonging Die Steel Lifespan in Operations

In industrial applications, maintaining the lifespan of die steel is crucial for ensuring efficiency and productivity. One of the most effective ways to prolong the life of die steel tools is through regular maintenance practices. This includes routine inspections to identify any signs of wear or damage early. Implementing a schedule for regular checks can prevent minor issues from escalating into major problems, thereby saving time and costs associated with repairs or replacements.

Additionally, proper cleaning and lubrication play a vital role in extending die steel lifespan. After each use, it’s important to remove any debris or residues that can cause corrosion or rust. Using appropriate lubricants helps reduce friction during operations, which can minimize wear and tear on the tool. Furthermore, storing die steel in a controlled environment, where temperature and humidity are regulated, also contributes significantly to maintaining its integrity and performance. By adopting these maintenance tips, industries can ensure that their die steel tools remain efficient and durable for longer durations, ultimately enhancing overall operational efficiency.

FAQS

: It's essential to consider the unique attributes of each die steel grade, including their mechanical properties, the impact of recent innovations in materials science, and advancements in manufacturing technologies such as 3D printing and laser powder bed fusion.

High-performance plain carbon steels, especially those produced through 3D printing, can offer tensile and impact properties that are comparable to ultra-high strength alloys, potentially prompting a reassessment of traditional die steel grades.

The laser powder bed fusion process allows for precise control over microstructure and defects, significantly enhancing the mechanical performance of die steels tailored to meet specific application requirements.

Regular maintenance helps identify early signs of wear or damage, preventing minor issues from escalating into major problems and thereby extending the lifespan and efficiency of die steel tools.

Effective maintenance includes routine inspections, proper cleaning to remove debris, appropriate lubrication to reduce friction, and controlled storage to maintain environmental conditions.

Die steel tools should be stored in a controlled environment with regulated temperature and humidity to prevent corrosion and deterioration, ensuring their performance remains intact.

Using appropriate lubricants minimizes friction during operations, which helps reduce wear and tear on die steel tools, ultimately contributing to their longevity.

It is important to clean die steel tools after each use to remove any debris or residues that can lead to corrosion or rust, thereby maintaining their functionality.

Unified stress-strain models provide insights into predicting material behavior under various loads, aiding engineers and designers in making informed decisions regarding steel grade selection based on enhanced performance parameters.

By following maintenance tips, industries can ensure their die steel tools remain efficient and durable, enhancing overall operational efficiency and reducing costs associated with repairs or replacements.

Conclusion

In the realm of industrial applications, understanding the various types of die steel is crucial for optimal performance and cost-effectiveness. Different die steel variants possess unique properties that influence their durability, resilience, and suitability for specific applications. This blog explores the key properties of die steel, including its performance characteristics across different grades, which are essential for manufacturers to consider when selecting materials for projects. It also highlights best practices in selecting die steel based on project needs and offers maintenance tips to extend the lifespan of die steel components in operations.

As a leader in the manufacturing of feed processing machinery, Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. emphasizes the significance of using high-quality die steel in the production of pellet mill dies. With over 25 years of expertise, our commitment to providing effective environmental solutions aligns with the industry’s demand for reliable and durable die steel options tailored to meet specific operational needs.

Related Posts

-

Exploring Unique Features and Applications of the Best Feed Pellet Machine in Your Operations

-

Unwavering Quality of Chinese Manufacturing in the Leading Pellet Mills for Feed

-

Revolutionizing Global Feed Production: China's Best Poultry Mash Feed Machine Leading the Charge

-

Solutions for Optimal Efficiency in Best Animal Feed Processing Machine Production

-

Drum Mixer Shaft: A Comprehensive Comparison of Materials and Designs for Optimal Performance

-

What is the Importance of Livestock Feed Pellet Mill in Modern Agriculture

Blog Tags: