7 Best Pellet Mill Equipment Innovations Transforming the Industry Today

Table of Contents

- Latest Developments in Pellet Mill Design and Efficiency

- Integrating Smart Technology for Enhanced Pellet Production

- Sustainability Innovations in Raw Material Processing

- Advancements in Die and Roller Manufacturing Techniques

- Energy Efficiency Improvements in Pellet Mill Operations

- Automated Systems for Monitoring and Quality Control in Pelleting

- FAQS

- Conclusion

- Related Posts

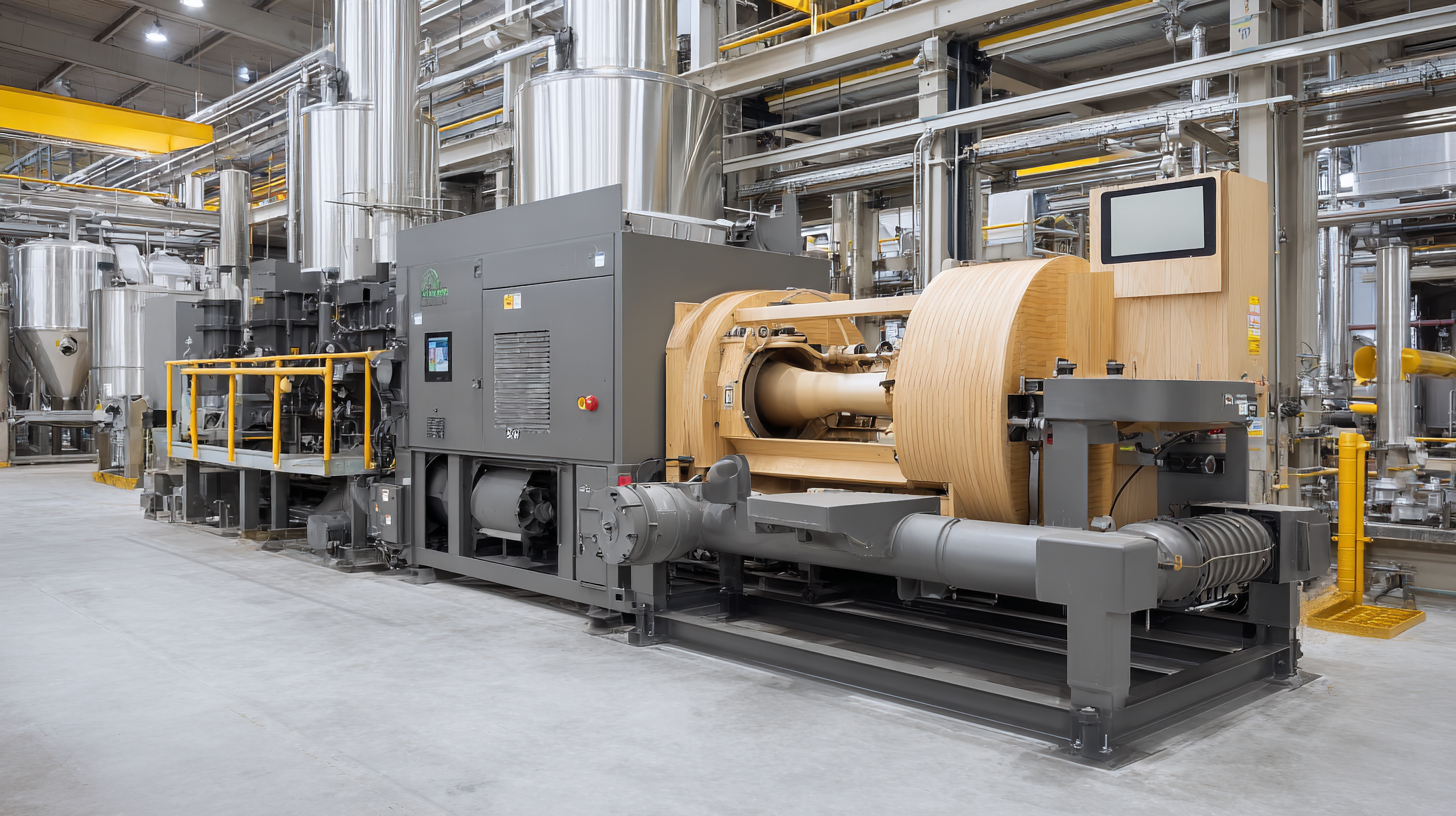

In the rapidly evolving landscape of feed processing, the innovation of Pellet Mill Equipment is reshaping the industry and enhancing production efficiency. At Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY), with over 25 years of experience, we specialize in manufacturing advanced feed processing machinery and high-quality pellet mill dies. Our commitment to environmental protection systems further solidifies our role as a leader in the feed plant and aquaculture farm solutions sector. This blog explores the seven best Pellet Mill Equipment innovations that are not only addressing common industry problems but also setting a benchmark for the future of feed production. By embracing these technologies, businesses can significantly improve their operational performance while contributing to sustainable practices. Join us as we delve into these transformative advancements that promise to revolutionize the pellet milling industry.

Latest Developments in Pellet Mill Design and Efficiency

The pellet mill industry is undergoing significant transformations thanks to the latest innovations in design and efficiency. Modern pellet mills now incorporate advanced technologies that not only streamline production processes but also enhance overall output quality. For instance, integrated automation systems help monitor and adjust parameters in real-time, significantly reducing downtime and ensuring consistent product quality.

Tip: When considering improvements for your pellet mill operations, investing in automation technology can result in substantial long-term savings.

Tip: When considering improvements for your pellet mill operations, investing in automation technology can result in substantial long-term savings.

Moreover, energy efficiency has become a primary focus of recent developments, with new designs prioritizing reduced power consumption while maintaining high performance. Enhanced die and roller designs minimize friction and wear, leading to longer service life and lower energy costs.

Tip: Regular maintenance and periodic upgrades of key components can greatly improve your mill's energy efficiency and overall performance.

These innovations not only drive productivity but also align with sustainability goals, making it a great time to explore updates in pellet mill technology. Enhanced designs are not just about speed; they also focus on producing high-quality pellets that meet stringent industry standards.

Integrating Smart Technology for Enhanced Pellet Production

The pellet production industry has witnessed significant advancements thanks to the integration of smart technology. Modern pellet mills are now equipped with innovative features that streamline operations and enhance productivity. These technologies allow for real-time monitoring of the production process, minimizing waste and increasing efficiency. By utilizing data analytics, producers can make informed decisions based on performance metrics, ultimately leading to higher quality pellets and optimized resource utilization.

Tip: When investing in pellet mill equipment, look for solutions that offer comprehensive software support. This can help in tracking the entire production lifecycle, enabling better control over parameters such as temperature, moisture levels, and product consistency.

Furthermore, automation plays a pivotal role in the evolution of pellet mills. Advanced systems can automate routine tasks, reducing labor costs and the likelihood of human error. Additionally, smart technology provides predictive maintenance features, which can notify operators of potential equipment failures before they occur, ensuring minimal downtime.

Tip: To maximize the benefits of automation, consider staff training. Ensuring that employees are skilled in using new technologies can significantly enhance the efficiency and output of your pellet production process.

7 Best Pellet Mill Equipment Innovations Transforming the Industry Today

Sustainability Innovations in Raw Material Processing

Sustainability is becoming a cornerstone in the pellet mill industry, driven by an increasing demand for eco-friendly practices and materials. Innovations in raw material processing are pivotal for reducing the carbon footprint associated with pellet production. According to the American Biomass Energy Association, approximately 70% of the biomass used for pellets comes from sustainable sources. This shift not only supports environmental goals but also holds economic benefits, as producers adopt more efficient processing techniques that minimize waste and enhance product yield.

Recent advancements highlight the use of advanced pretreatment technologies, such as steam explosion and enzymatic hydrolysis, which improve the digestibility of raw materials. A report by the International Energy Agency indicates that implementing these technologies can increase pellet output by up to 30%. Moreover, the adoption of circular economy principles, where waste from one process becomes the feedstock for another, exemplifies the changing landscape of the industry. By redefining how raw materials are sourced and processed, pellet mills are not only elevating their sustainability efforts but also improving their competitiveness in a rapidly evolving market.

Advancements in Die and Roller Manufacturing Techniques

Advancements in die and roller manufacturing techniques have significantly enhanced the efficiency and performance of pellet mill equipment. Innovative materials and precise engineering processes have led to the development of dies and rollers that exhibit superior durability and wear resistance. This means that manufacturers can produce pellets at higher rates without facing the common issues of equipment wear and tear, ultimately reducing downtime and maintenance costs. Moreover, these advanced components can be tailored to specific production needs, ensuring that different types of biomass can be processed effectively.

Furthermore, the use of computer-aided design (CAD) and advanced simulation techniques has revolutionized the design of dies and rollers. These technologies allow for the optimization of shapes and profiles, improving the overall flow and compression of materials during the pelleting process. As a result, manufacturers are able to achieve higher pellet quality while minimizing energy consumption. This not only supports sustainability efforts but also enhances the operational efficiency of pellet mills, making them more competitive in an ever-evolving industry.

Energy Efficiency Improvements in Pellet Mill Operations

In recent years, the pellet mill industry has witnessed remarkable innovations aimed at enhancing energy efficiency. According to a report from the U.S. Department of Energy, advancements in pellet mill technology can improve energy consumption by up to 20%. Innovations such as variable frequency drives and advanced conditioning systems allow mills to optimize power usage during production, significantly reducing operational costs.

Moreover, the integration of smart sensors in pellet mills facilitates real-time monitoring of energy consumption. This ensures processes are running at peak efficiency and enables quick adjustments to minimize waste. Researchers at the National Renewable Energy Laboratory highlight that these smart technologies not only enhance production but also contribute to sustainability goals by lowering the carbon footprint of operations.

**Tips**: To further improve energy efficiency in your pellet mill operations, consider conducting regular energy audits. Identifying high-consumption areas can help you implement targeted upgrades. Additionally, training your team on energy management practices can lead to a more conscious and efficient workplace, driving overall productivity. Experimenting with alternative feedstock materials may also yield better energy economics, thus improving both efficiency and profitability in the long run.

7 Best Pellet Mill Equipment Innovations Transforming the Industry Today - Energy Efficiency Improvements in Pellet Mill Operations

| Innovation | Description | Energy Savings (%) | Implementation Year |

|---|---|---|---|

| High-efficiency Die Design | Enhanced die designs that optimize material flow and reduce energy consumption. | 15% | 2020 |

| Variable Frequency Drives (VFD) | Using VFDs to control the speed of motors for improved energy efficiency. | 20% | 2019 |

| Self-cleaning Systems | Innovative self-cleaning mechanisms that reduce downtime and energy waste. | 10% | 2021 |

| Heat Recovery Systems | Systems to capture waste heat and reuse it within the operation. | 25% | 2020 |

| Energy Monitoring Solutions | Advanced monitoring systems to track energy usage and efficiency. | 12% | 2018 |

| Enhanced Lubrication Systems | New lubrication technology to reduce friction and improve system efficiency. | 18% | 2022 |

| Smart Automation Systems | Integration of AI for predictive maintenance and optimal operation. | 22% | 2023 |

Automated Systems for Monitoring and Quality Control in Pelleting

In recent years, the pellet mill industry has undergone substantial technological advancements, particularly in the realm of automated systems for monitoring and quality control. According to a report by Mordor Intelligence, the global pellet mill market is projected to grow at a CAGR of 5.2% from 2021 to 2026, emphasizing the increasing emphasis on efficiency and quality. Automated monitoring systems now allow operators to track variables such as moisture content, feed consistency, and temperature in real time, ensuring that the pelleting process maintains optimal conditions to produce high-quality pellets.

Quality control has also seen significant improvements through the integration of machine learning algorithms and AI technologies. These innovations facilitate predictive maintenance, where equipment can alert operators to potential issues before they escalate, reducing downtime by up to 30%, as reported in a study by the International Journal of Advanced Manufacturing Technology. By implementing such systems, manufacturers not only enhance product quality but also optimize energy consumption, leading to more sustainable production processes. The blend of automation and data analytics positions the pellet mill industry at the forefront of technological evolution, driving advancements that will define the future of pelleting operations.

FAQS

: Modern pellet mills incorporate advanced technologies that streamline production processes, enhance output quality, and utilize integrated automation systems for real-time monitoring and adjustments.

Automation reduces downtime, minimizes waste, lowers labor costs, and enhances overall productivity by automating routine tasks and providing predictive maintenance features.

Investing in regular maintenance, periodic upgrades, and enhanced die and roller designs can significantly improve a mill's energy efficiency and performance.

Innovations in materials and engineering have led to dies and rollers that are more durable and wear-resistant, allowing for higher production rates and reduced maintenance costs.

Data analytics enables producers to make informed decisions based on performance metrics, leading to higher quality pellets and optimized resource utilization.

Smart technology streamlines operations, allows real-time monitoring, minimizes waste, and supports predictive maintenance to prevent equipment failures.

Staff training should focus on skills related to using new automation and smart technologies to enhance efficiency and output in pellet production.

Recent developments prioritize energy efficiency and high-quality pellet production, which supports sustainability efforts while improving operational efficiency.

Look for equipment that offers comprehensive software support for tracking production lifecycle parameters like temperature, moisture levels, and product consistency.

CAD and advanced simulation techniques allow for optimization of shapes and profiles, improving material flow and compression, resulting in higher pellet quality and lower energy consumption.

Conclusion

In the ever-evolving landscape of pellet production, Pellet Mill Equipment is at the forefront of innovation, driving significant advancements in efficiency and sustainability. Recent developments in pellet mill design focus on enhancing production capabilities while integrating smart technology, which streamlines operations and optimizes output. Companies like Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. are paving the way by specializing in the manufacturing of high-quality feed processing machinery and pellet mill dies, reflecting over 25 years of expertise in the industry.

Moreover, the incorporation of sustainable practices in raw material processing not only improves environmental impact but also meets the growing demand for eco-friendly production methods. Advancements in die and roller manufacturing techniques, along with energy efficiency improvements, further enhance Pellet Mill Equipment operations. Automated systems for monitoring and quality control ensure consistent product quality, signifying a transformative era in pellet production that prioritizes both performance and sustainability.

Related Posts

-

7 Essential Features of the Best Poultry Feed Machine for Global Buyers

-

Global Excellence in Pellet Mill Parts from China's Leading Factory

-

How to Choose the Best Pellet Making Machine for Your Business Needs

-

Ultimate Guide to Choosing the Best Hammer Mill for Your Manufacturing Needs

-

7 Compelling Reasons Your Next Investment Should Be the Best Feed Mill Plant

-

Revolutionizing Global Feed Production: China's Best Poultry Mash Feed Machine Leading the Charge

Blog Tags: