Advantages of Utilizing a Drum Mixer Shaft in Your Production Process

Table of Contents

- Advantages of Drum Mixer Shafts: Enhancing Efficiency in Production Processes

- The Role of Drum Mixer Shafts in Reducing Production Costs

- Improving Product Consistency with Advanced Drum Mixer Shaft Designs

- Industry Insights: How Drum Mixer Shafts Optimize Material Handling

- Comparative Analysis of Drum Mixer Shafts and Traditional Mixing Methods

- Case Studies: Successful Implementations of Drum Mixer Shafts in Manufacturing

- FAQS

- Conclusion

- Related Posts

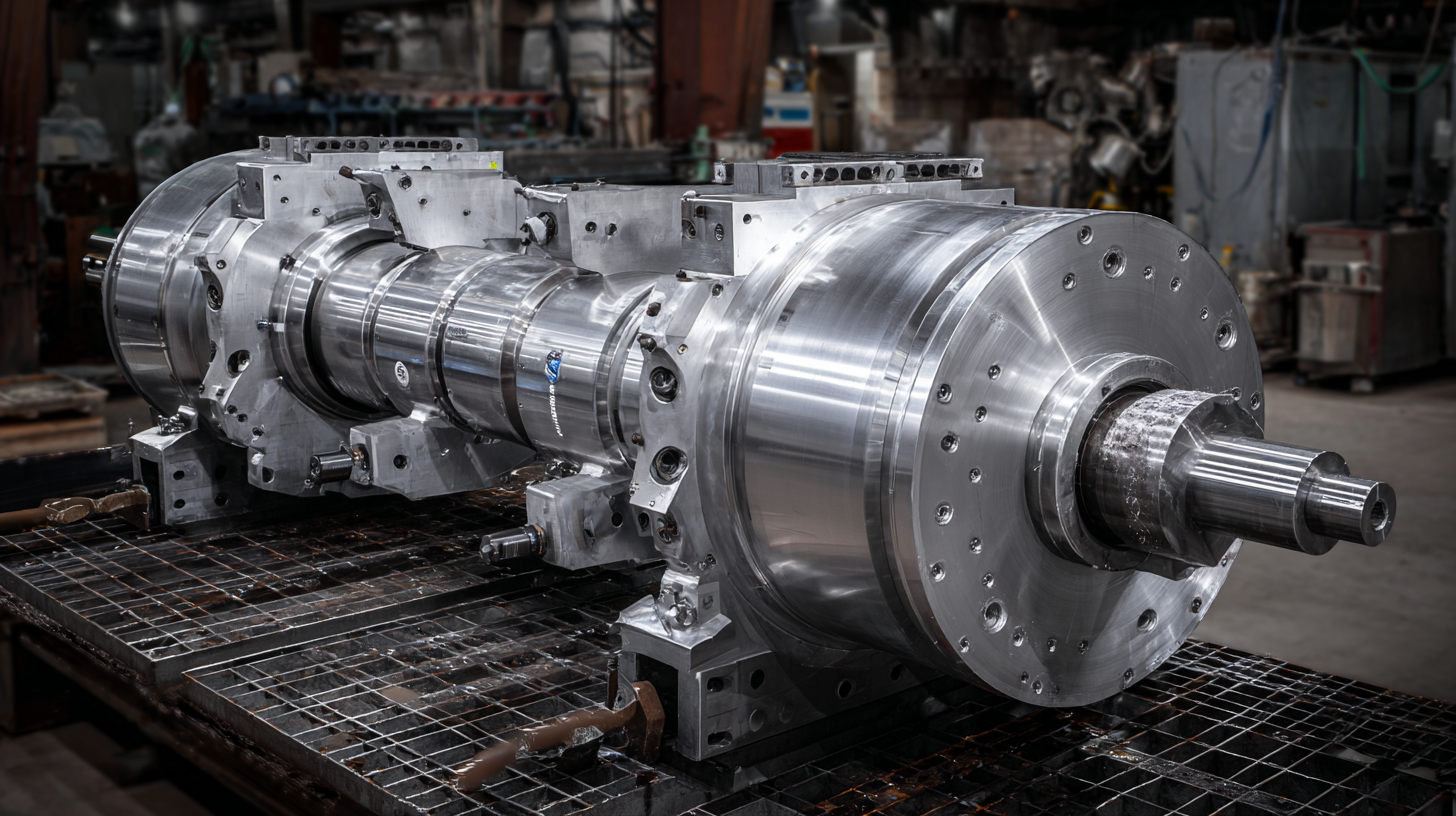

In the ever-evolving landscape of manufacturing, the efficiency and effectiveness of production processes play a pivotal role in determining a company's success. One key component that has significantly enhanced operational capabilities is the Drum Mixer Shaft. At Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., or CPSHZY, we have dedicated over 25 years to the design and production of advanced feed processing machinery, including innovative solutions for pellet mill dies. By integrating a Drum Mixer Shaft into your production process, you can achieve superior mixing performance, improve product consistency, and optimize energy consumption. The advantages of utilizing this technology extend beyond mere efficiency; they encompass enhanced product quality and reduced operational costs, making it a valuable asset for feed plants and aquaculture farms aiming for sustainability and growth.

Advantages of Drum Mixer Shafts: Enhancing Efficiency in Production Processes

Drum mixer shafts are increasingly becoming essential in modern production processes. Their design optimally blends materials, ensuring uniform consistency and quality in the final product. By utilizing a drum mixer shaft, manufacturers can significantly enhance operational efficiency, reduce processing times, and minimize material waste, leading to overall cost savings.

One tip for maximizing the benefits of drum mixer shafts is to regularly inspect and maintain the equipment. Ensuring that the shaft and associated components are in good condition can prevent unexpected breakdowns and maintain production flow. Additionally, calibrating the speed settings according to the material being mixed can lead to better blending outcomes and improved product quality.

Another advantage of drum mixer shafts is their versatility. They can easily be adapted to various materials, including dry powders and liquid mixtures, making them ideal for diverse production environments. When implementing a drum mixer shaft, consider experimenting with different blending techniques or configurations to find the most efficient method for your specific materials.

Advantages of Utilizing a Drum Mixer Shaft in Your Production Process

The Role of Drum Mixer Shafts in Reducing Production Costs

Drum mixer shafts play a crucial role in optimizing production processes, particularly in their capacity to significantly reduce production costs.

According to a report by the American Society of Mechanical Engineers, properly designed mixer shafts can decrease energy consumption by as much as 20%

when compared to less efficient alternatives. This efficiency stems from their ability to mix materials evenly and maintain consistent viscosity, which reduces

the time and energy needed for production.

Drum mixer shafts play a crucial role in optimizing production processes, particularly in their capacity to significantly reduce production costs.

According to a report by the American Society of Mechanical Engineers, properly designed mixer shafts can decrease energy consumption by as much as 20%

when compared to less efficient alternatives. This efficiency stems from their ability to mix materials evenly and maintain consistent viscosity, which reduces

the time and energy needed for production.

Moreover, the durability and design of drum mixer shafts contribute to lower maintenance expenses. A study conducted by the Industrial Mixer Association revealed that businesses using advanced drum mixer shaft technology experienced a 30% reduction in downtime due to fewer mechanical failures and enhanced operational reliability. By investing in high-quality drum mixer shafts, manufacturers not only achieve higher productivity but also significantly cut down on ongoing operational costs, further solidifying their position in a competitive market.

Improving Product Consistency with Advanced Drum Mixer Shaft Designs

In today's competitive manufacturing landscape, maintaining consistent product quality is crucial. Advanced drum mixer shaft designs play a key role in achieving this consistency. According to a report by MarketsandMarkets, the global mixing equipment market is projected to grow from $15.5 billion in 2020 to $20.3 billion by 2025, highlighting the increasing importance of innovative mixing solutions in production processes. Drum mixer shafts offer superior mixing performance due to their efficient design, ensuring uniform distribution of materials and reduced batch variability.

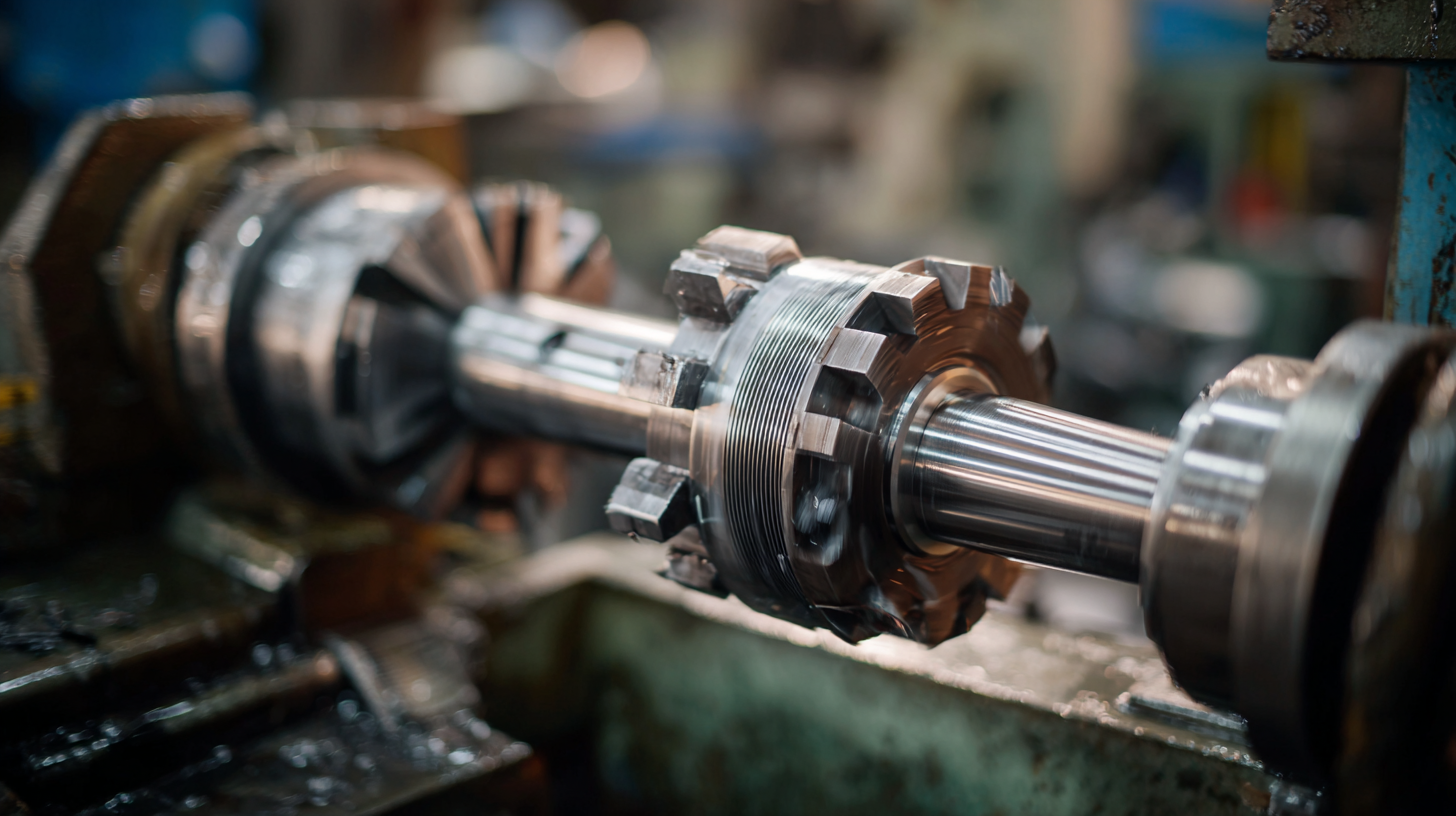

To enhance product consistency, manufacturers should consider incorporating tapered or multi-shaft designs in their drum mixers. Tapered shafts can facilitate better material flow and prevent clumping, while multi-shaft configurations can handle highly viscous substances more effectively. This flexibility enables businesses to adapt to varying production needs while ensuring high-quality outputs.

Tips: When selecting a drum mixer shaft, look for features such as adjustable speed settings and easy disassembly for maintenance. Additionally, implementing regular performance evaluations can help identify potential inconsistencies early in the production process, allowing for timely adjustments and continuous improvement in product quality. Investing in advanced drum mixer shaft technologies not only enhances consistency but also boosts overall operational efficiency.

Industry Insights: How Drum Mixer Shafts Optimize Material Handling

In modern production processes, the utilization of drum mixer shafts has emerged as a critical component for optimizing material handling. These shafts are designed to enhance the efficiency and uniformity of mixing operations, providing a consistent quality of the final product. Their robust construction allows them to handle various materials, from dry powders to viscous liquids, ensuring versatility across different industries. By facilitating thorough mixing, drum mixer shafts significantly reduce the time required for production cycles, ultimately leading to increased throughput and lower operational costs.

Moreover, drum mixer shafts contribute to better material management by minimizing waste and improving product quality. The design of these shafts promotes a homogeneous blend, preventing segregation and ensuring that ingredients are evenly distributed. This optimization is especially beneficial in industries such as food, pharmaceuticals, and chemicals, where precise formulations are essential.

Additionally, the integration of advanced technology, such as variable speed drives, allows for further customization of the mixing process, providing manufacturers with greater control over their production workflows and enhancing overall effectiveness.

Comparative Analysis of Drum Mixer Shafts and Traditional Mixing Methods

The utilization of drum mixer shafts in industrial processes offers distinct advantages when compared to traditional mixing methods. A recent comparative analysis highlights the mixing behavior in advanced mixing setups, such as twin-paddle blenders, which utilize discrete element method (DEM) alongside experimental techniques to explore flow patterns and mixing mechanisms. These studies reveal that non-spherical particle dynamics significantly influence the overall mixing efficiency, an aspect that traditional mixers often overlook. By employing drum mixer shafts, manufacturers can minimize inconsistencies in particle distribution, thereby enhancing product uniformity.

Further investigations have demonstrated that the type of mixer and mixing durations directly affect the properties of multipurpose mortars, showcasing that the precision of mixing equipment can lead to better performance of industrial materials in both fresh and hardened states. Reports indicate that optimized mixing times combined with the unique design of drum mixer shafts contribute to improved material characteristics. Such advancements underscore the importance of selecting the appropriate mixer type to achieve desired outcomes while maintaining efficiency in production processes.

Case Studies: Successful Implementations of Drum Mixer Shafts in Manufacturing

In recent years, several manufacturing companies have turned to drum mixer shafts to enhance their production processes, achieving significant improvements in efficiency and consistency. For instance, a global leader in the food processing sector adopted a drum mixer shaft to revolutionize its mixing operations. By integrating this robust technology, the company not only reduced mixing time by 30% but also ensured uniformity in ingredient blends, leading to higher product quality and lower waste levels.

Another compelling case comes from the construction materials industry, where a major manufacturer implemented a drum mixer shaft to optimize its concrete mixing process. The results were remarkable; the company experienced a 25% increase in production output while maintaining compliance with stringent industry standards. The durable design of the drum mixer shaft minimized downtime due to maintenance issues, thereby boosting overall operational efficiency and profitability. These success stories highlight the transformative impact that drum mixer shafts can have across various manufacturing sectors.

Advantages of Utilizing a Drum Mixer Shaft in Your Production Process

| Case Study | Industry | Key Benefits | Outcome |

|---|---|---|---|

| Case Study 1 | Food & Beverage | Improved Mixing Efficiency | 30% Faster Production |

| Case Study 2 | Chemical Processing | Consistent Product Quality | Reduced Batch Variability |

| Case Study 3 | Pharmaceuticals | Enhanced Material Homogeneity | Higher Yield Rates |

| Case Study 4 | Construction Materials | Reduced Energy Consumption | 15% Lower Operational Costs |

| Case Study 5 | Cosmetics | Faster Product Turnaround | Improved Time-to-Market |

FAQS

: Drum mixer shafts enhance operational efficiency, reduce processing times, and minimize material waste, leading to overall cost savings and improved consistency and quality in the final product.

Manufacturers can maximize benefits by regularly inspecting and maintaining the equipment, ensuring components are in good condition, and calibrating speed settings according to the material being mixed.

Drum mixer shafts are versatile and can handle various materials, such as dry powders and liquid mixtures, making them suitable for diverse production environments.

Drum mixer shafts enhance mixing efficiency and uniformity, leading to consistent product quality while reducing production cycle times and operational costs.

Drum mixer shafts are especially beneficial in industries such as food, pharmaceuticals, and chemicals, where precise formulations and consistent blending are essential.

The integration of advanced technology, such as variable speed drives, allows for customization of the mixing process, giving manufacturers greater control over production workflows.

Drum mixer shafts offer distinct advantages over traditional mixers by minimizing inconsistencies in particle distribution and enhancing product uniformity, which traditional methods often overlook.

The type of mixer and mixing durations directly affect the properties of multipurpose mortars, with optimized mixing times leading to better material performance in both fresh and hardened states.

The unique design of drum mixer shafts promotes homogeneous blending, preventing segregation and ensuring that ingredients are evenly distributed for higher product quality.

When implementing a drum mixer shaft, manufacturers should experiment with different blending techniques and configurations to determine the most efficient mixing method for their specific materials.

Conclusion

In the modern manufacturing landscape, the utilization of a Drum Mixer Shaft can significantly enhance production efficiency and product consistency. By integrating advanced Drum Mixer Shaft designs, companies can experience reduced production costs and improved handling of materials, which is vital for maintaining competitive advantage. This technology not only streamlines the mixing process but also ensures uniformity in product quality, essential for industries such as feed processing and aquaculture.

Moreover, comparative analyses indicate that Drum Mixer Shafts outperform traditional mixing methods in several aspects, offering greater reliability and performance. Case studies highlight successful implementations in manufacturing settings, showcasing the transformative impact of this technology. At Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., with over 25 years in the industry, we emphasize the importance of innovative solutions like the Drum Mixer Shaft to support our clients in achieving operational excellence.

Related Posts

-

Discover Top Quality Cattle Feed Mixer Machines from China for Your Global Partnership Needs

-

Essential Guide to Maximizing Efficiency with Vertical Shaft Cement Mixers Checklist

-

Exploring Unique Product Attributes for the Best Feed Mill Process and How to Choose the Right One

-

Choosing the Right Manufacturer for the Best Pellet Making Machine for Poultry Feed and Key Comparisons

-

What is the Optimal Feed Mill Process for Global Sourcing Success?

-

7 Essential Features of the Best Poultry Feed Machine for Global Buyers

Blog Tags: